Post the MSDS and a picture of the product maybe we can help.

I have made good strong nitric acid from battery acid, nitrates are all around you (Heck your pee could be made into nitric with a lot of work and time), even a caveman can make it from rocks H2SO4 and dirt from the cave floor KNO3, countries, kings, and governments have power through history because of nitrates, nitrates are all around us, countries used to tax their population being paid in nitrates from the farmers, there is a way to find a source for nitric, no matter what country tries to stop you, you just have to learn and figure out how. they are used all around you in some form or another.

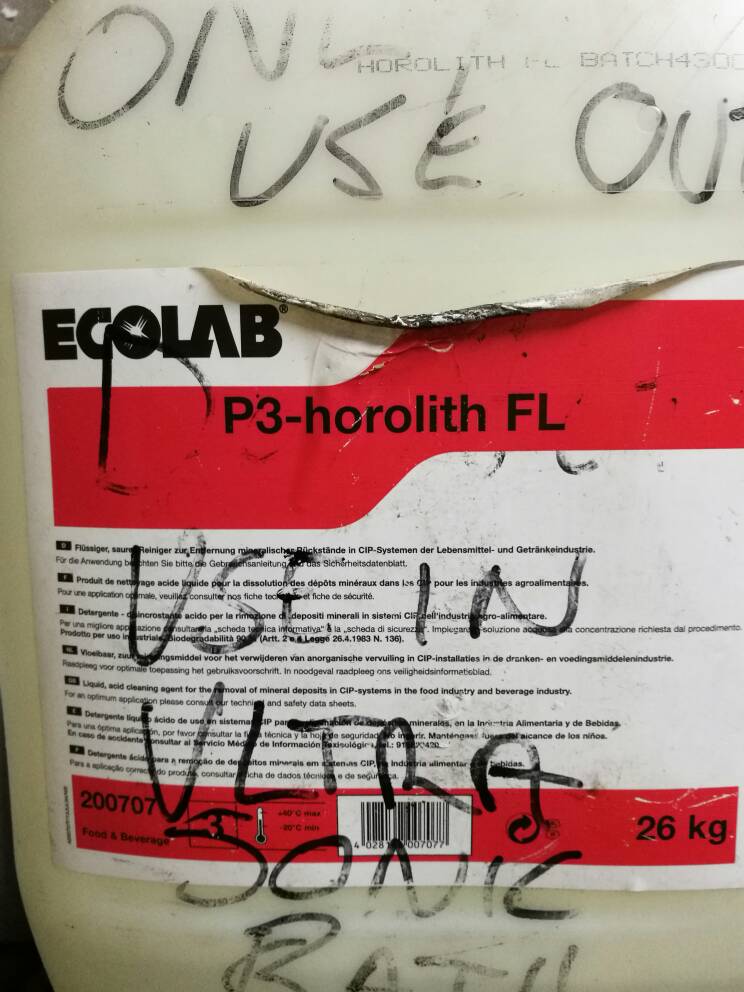

There deliming solutions that I know of, that contain up to about 30% nitric acid and as much as 40% phosphoric acid (normally the nitric is very dilute say 5%, with phosphoric acid being the major component of the deliming solution. used for cleaning plumbing, food and dairy equipment... Primarily to remove calcium and magnesium salts, phosphoric acid is used to passivate the Iron alloys against corrosion by the dilute nitric acid.

Some delimers even have additives like hydrochloric acid which may cause problems for making nitric (for silver for example).

Some delime solutions also use hydrofluoric acid which is fairly volitile something we would not be wanting to mess around with here.

Phosphoric acid can be used in distilling nitric acid, whether you can from the chemical you have may depend on its composition.

Phosphoric acid is pretty much a non-volatile acid (boiling point above somewhere above 300deg. F), that can displace NOx from a nitrate salt. Phosphoric acid can also be concentrated by evaporation (much like nitric acid can up to its azeotropic composition with water around 68% HNO3), only phosphoric can be made much stronger I believe somewhere around 80% (if My memory works, which is not very good).