You must have missed it. Type in coin dies it will come up.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Silver Melting and Molding

- Thread starter Redeemed19

- Start date

Help Support Gold Refining Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

upcyclist

Well-known member

Redeemed:So I am looking into finding a mold for my blanks that are the correct diameter and height. I have gotten a few quotes but they are asking as much for graphite molds as I paid for the stamping dies. Lol

Your best bet is to find a premade mold in the diameter you want. Rather than trying to get the perfect height, just get a mold that is at least deep enough. Try different weights in it (1/2 ozt, 1/4 ozt, etc.) and see if you like the thickness. You can even start thick and file it down to your desired height. Once you get that height, weigh it. Pour by weight and not height.

Try looking for "round ingot molds" - I found this one on Amazon with 3 sizes.

Also, dig around the forums for help on pouring ingots well--one tip is to make sure your mold is hot and sooted.

Redeemed is correct. The weigh is the key. If you hit/press the die hard enough it will round itself out. If you want it thicker. Make it weight more.

I've done some research but haven't made any coins yet. For my day job, last year I ordered a batch of brass coins called challenge coins. You work with them to make the 3d art and then they feed it to a cnc that cuts the die. The cost is a few hundred for the die but the quality is breathtaking (I had a dragon with textured scales).

I understand that 50+ tons of pressure is what's needed for silver (but I wonder if I can hot press (just-off molten) at substantially lower pressures. I can find a short-travel hydraulic piston that can manage 50 tons but haven't worked out a frame yet. Incredibly dangerous at these pressures.

I understand that 50+ tons of pressure is what's needed for silver (but I wonder if I can hot press (just-off molten) at substantially lower pressures. I can find a short-travel hydraulic piston that can manage 50 tons but haven't worked out a frame yet. Incredibly dangerous at these pressures.

Challenge Coins, I've got a pile of them from my time in the military. The story behind them is they usually have the rank of the person who awarded you the coin. When you go out for drinks, everyone is required to pull out a coin, the lowest ranking coin ends up buying a round (or worse yet if you get challenged and don't have a coin with you!) I lost interest in them once my wife got a coin from General Dempsey. She still likes to brag about that and she wasn't even in the military.

upcyclist

Well-known member

I understand that 50+ tons of pressure is what's needed for silver (but I wonder if I can hot press (just-off molten) at substantially lower pressures. I can find a short-travel hydraulic piston that can manage 50 tons but haven't worked out a frame yet. Incredibly dangerous at these pressures.

You betcha. The price differences after 20 tons go up real fast (like exponential), but if you buy a press vice make one, you won't have to worry nearly as much about potentially fatal failures. Let's see, 50 tons of pressure, 1/2 square inch of flying metal fragment, that makes 100,000 PSI...

It's probably a premium price, but for scale, Bonny Doon's basic 20-ton press retails for $995, and their 55-ton press is $12k+. But your peace of mind, and possibly your face, should be worth more than that.

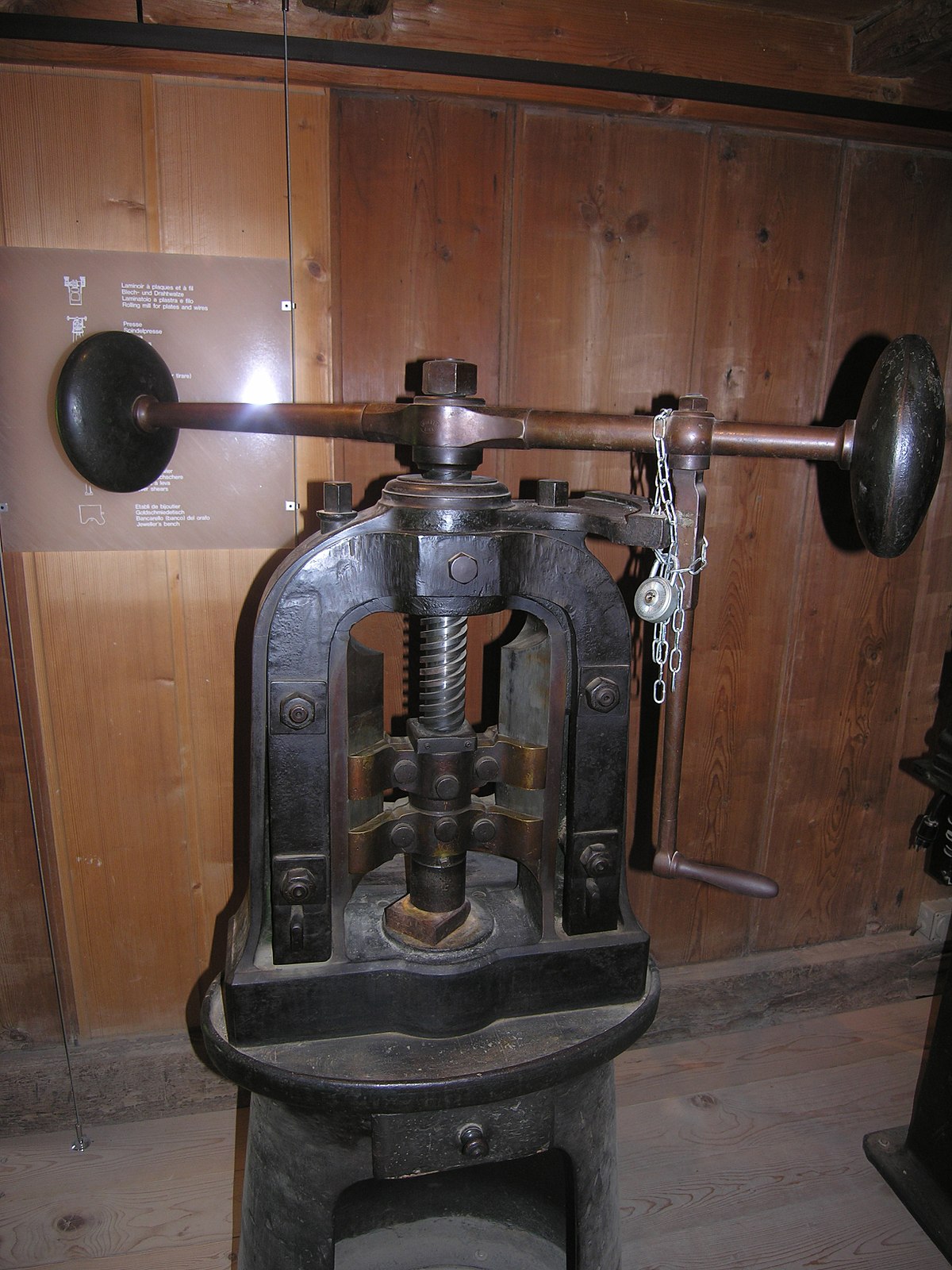

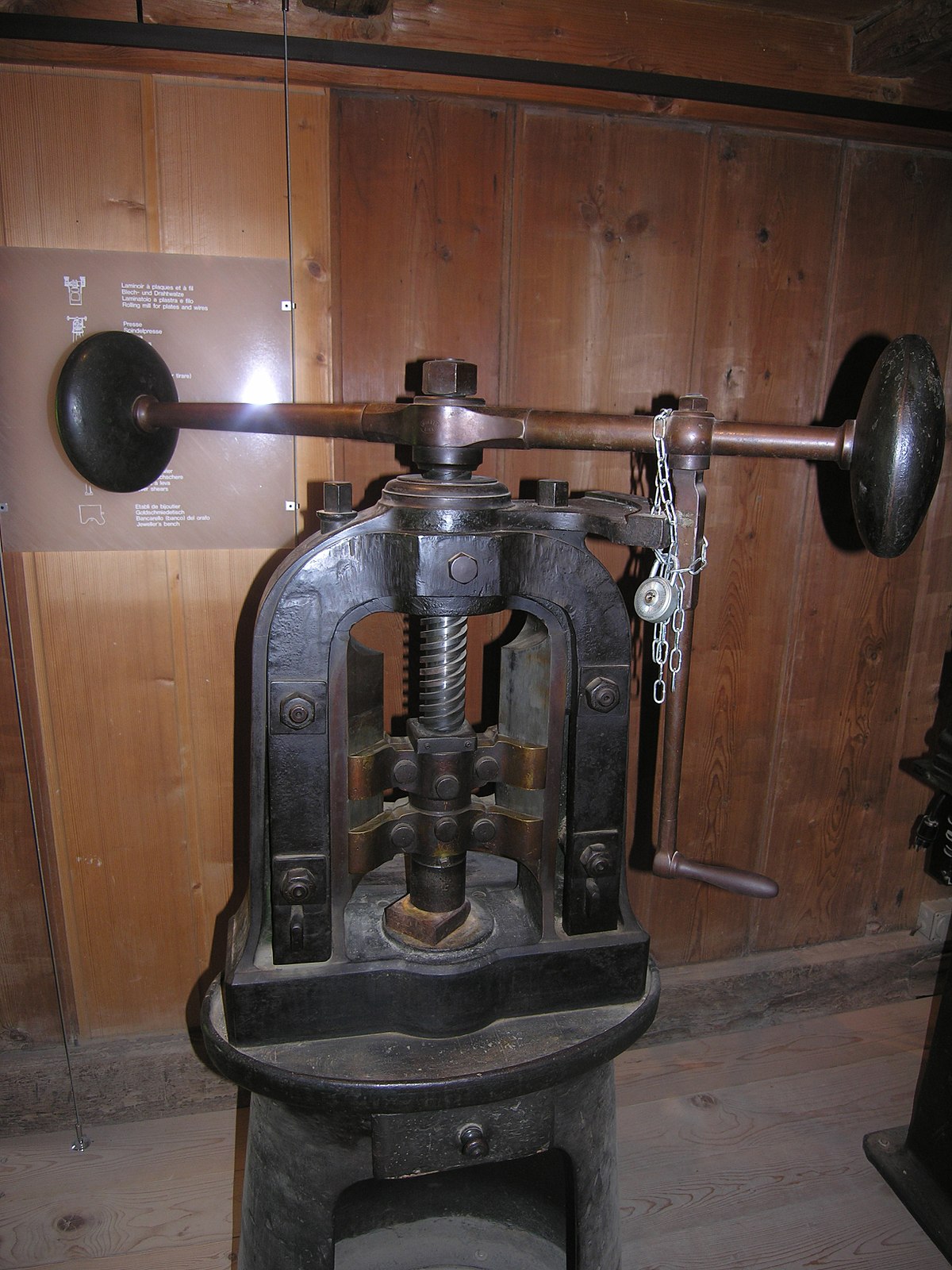

i worked for few years with screw press, making custom coins from pre-made brass or copper discs for souvenir shop, closely to the size of the 1ozt gold ones. it was a historic manual machine from like 40s or 50s, building your muscles quickly as some days you should make some 200 rounds  tiring but interesting work.

tiring but interesting work.

i never needed to cast my own "empty" coins, but working with copper was relatively efortless, compared to brass. but after heat treatment, brass was much easier to press (as expected, but oxidation patterns should be sanded off and roughly polished before). i am assuming that pure gold or silver would be soft enough to mint at home with some basic press, but i am concerned about diameter.

maybe some sacrifice of diameter could be beneficial for you, because pressing area will reduce significantly (sqare order). you could than use much less pressing power to obtain good results.

i personally would not use hand held hammer, espetially on high end matrices (brittle, extremely wear resistant steel). maybe some sort of falling weight would assure the proper direction of force

when attempted to hit another time after the die moved from position after the first whack, "focus" the dies by means of turning them gently, and you will hear a "click" - mint on the coin properly fit the die, and then you can whack again without making "double pressed" coin

wishing luck with this beautiful hobby

illustrative picture of the machine, one that i operated was somewhat bigger, but man... it weights somwhere about 2 tonnes delivery of the dissasembled thing and properly getting it to the room, and assembly of the thing onto two cubic meters of concrete (so it wouldn´t dance around)... that was hell of a work

delivery of the dissasembled thing and properly getting it to the room, and assembly of the thing onto two cubic meters of concrete (so it wouldn´t dance around)... that was hell of a work  4 man, 2 days

4 man, 2 days

i never needed to cast my own "empty" coins, but working with copper was relatively efortless, compared to brass. but after heat treatment, brass was much easier to press (as expected, but oxidation patterns should be sanded off and roughly polished before). i am assuming that pure gold or silver would be soft enough to mint at home with some basic press, but i am concerned about diameter.

maybe some sacrifice of diameter could be beneficial for you, because pressing area will reduce significantly (sqare order). you could than use much less pressing power to obtain good results.

i personally would not use hand held hammer, espetially on high end matrices (brittle, extremely wear resistant steel). maybe some sort of falling weight would assure the proper direction of force

when attempted to hit another time after the die moved from position after the first whack, "focus" the dies by means of turning them gently, and you will hear a "click" - mint on the coin properly fit the die, and then you can whack again without making "double pressed" coin

wishing luck with this beautiful hobby

illustrative picture of the machine, one that i operated was somewhat bigger, but man... it weights somwhere about 2 tonnes

upcyclist

Well-known member

If your blanks are air-cooled after casting, you should have relatively little problem pressing them. If you have worked them at all (e.g., cut them in a press, a lot of filing, more than a cursory polish), you'll want to anneal them again before pressing. Hot pressing shouldn't be necessary--if you don't heat the die as well, you're also giving them a bit of a thermal shock (though that may not matter, unless there's already a crack in them).