I have a large amount of old glass resistors, well a few pounds, that can be picked up with a Magnet , so I think they are steel core

I tested these and they are gold coated, What is the best way to recover the Gold from these ? I wanted to try AP but was scared to because of the steel content.

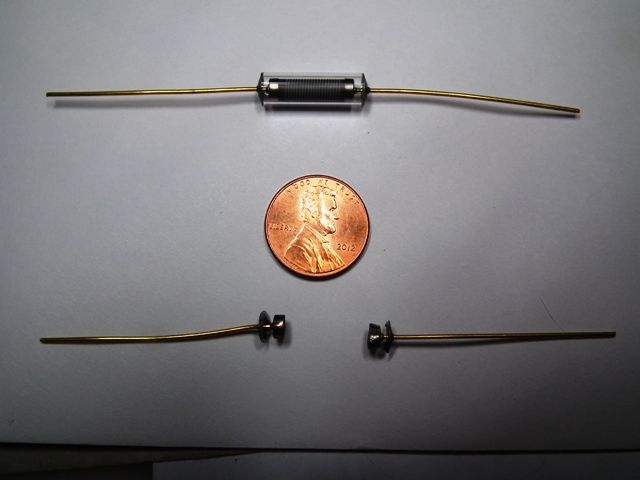

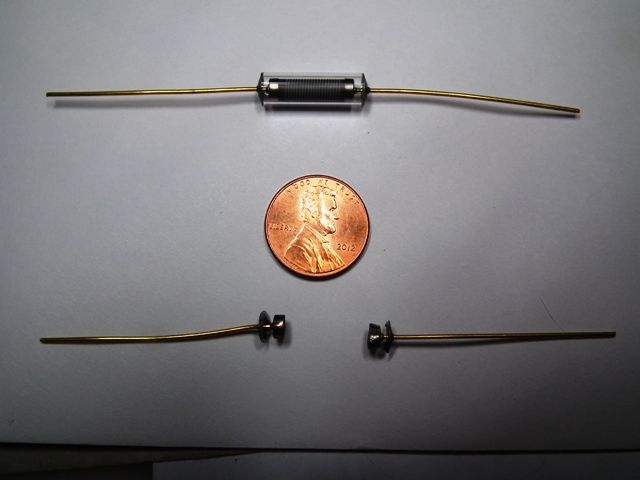

(Top picture is the part, penny is just for size, below is resistor taken apart ready to be scraped)

I'm new at this and have not tryed to recover yet, I have read Hoke books and have done a lot of reading here also, of course I can use more help !!

I tested these and they are gold coated, What is the best way to recover the Gold from these ? I wanted to try AP but was scared to because of the steel content.

(Top picture is the part, penny is just for size, below is resistor taken apart ready to be scraped)

I'm new at this and have not tryed to recover yet, I have read Hoke books and have done a lot of reading here also, of course I can use more help !!