If just HCl was used no values would dissolve, straight HCl will not dissolve copper without an oxidizer like air, oxygen, or diluted hydrogen peroxide, if using an strong oxidizer like 30% hydrogen peroxide or nitric then the values can dissolve into solution, but if elemental base metals are un-dissolved the base metal will displace the values from solution, the base metal will dissolve into solution (oxidize losing electrons) and the values will cement onto remaining base metal or form insoluble metal powders, as the base metal is oxidized it gives electrons to the more valuable metal in solution so that the oxidized values become metal again (reduced gain of electrons).

So to answer your question the stannous chloride will not test for values that are not dissolved into solution (oxidized).

If you did not dissolve the values into solution you will not have any values to detect in solution with the stannous chloride test.

If you dissolved the values, but not totally dissolve all of the base metals were not totally dissolved you may not have values in solution, although you could by chance have some.

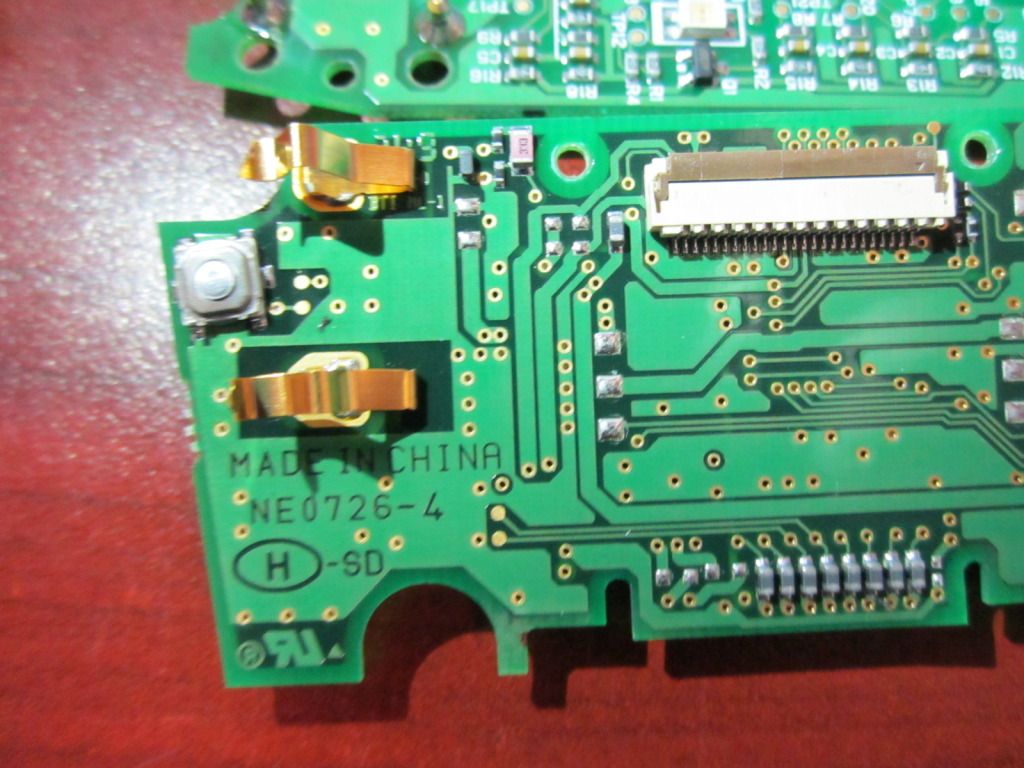

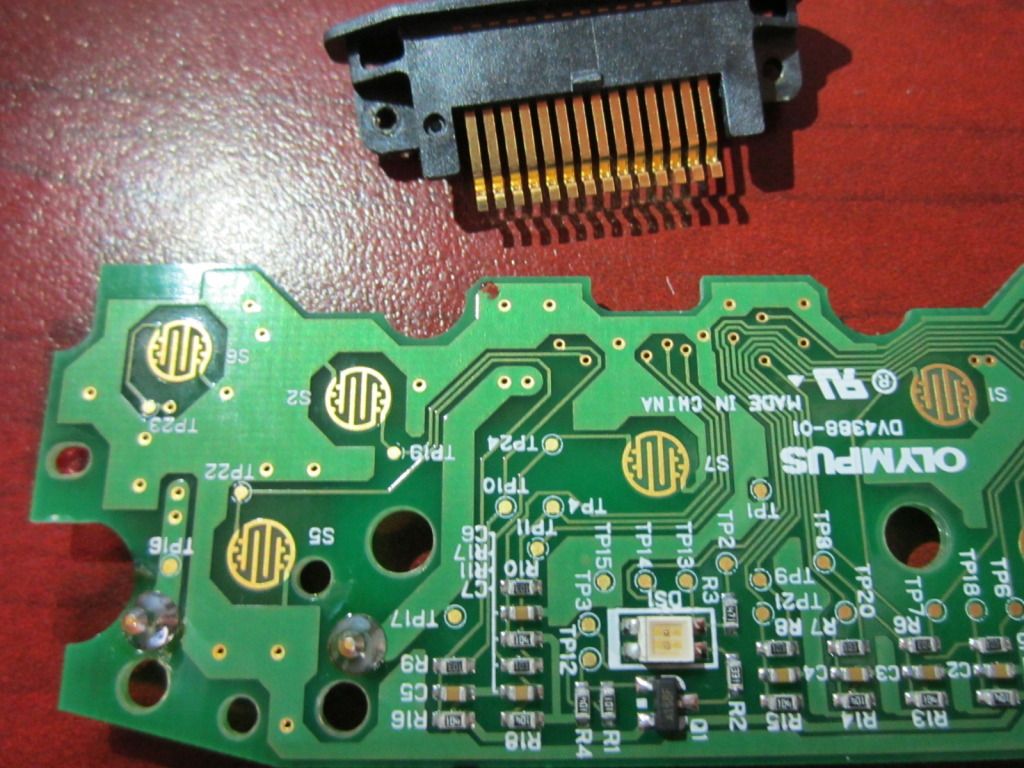

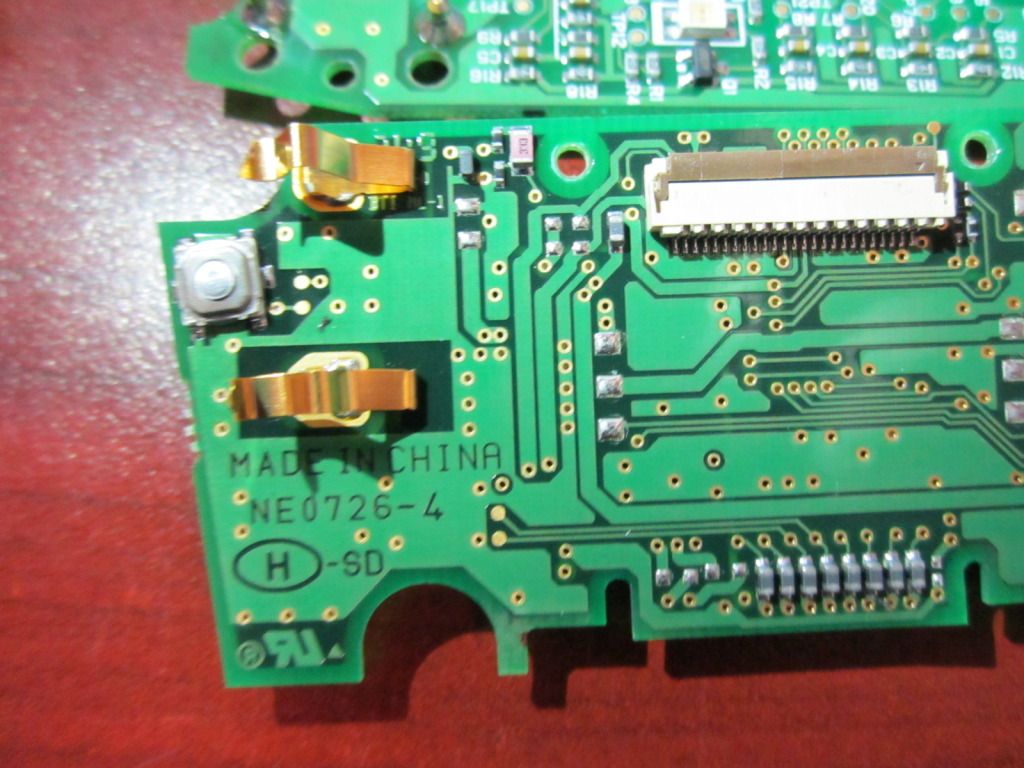

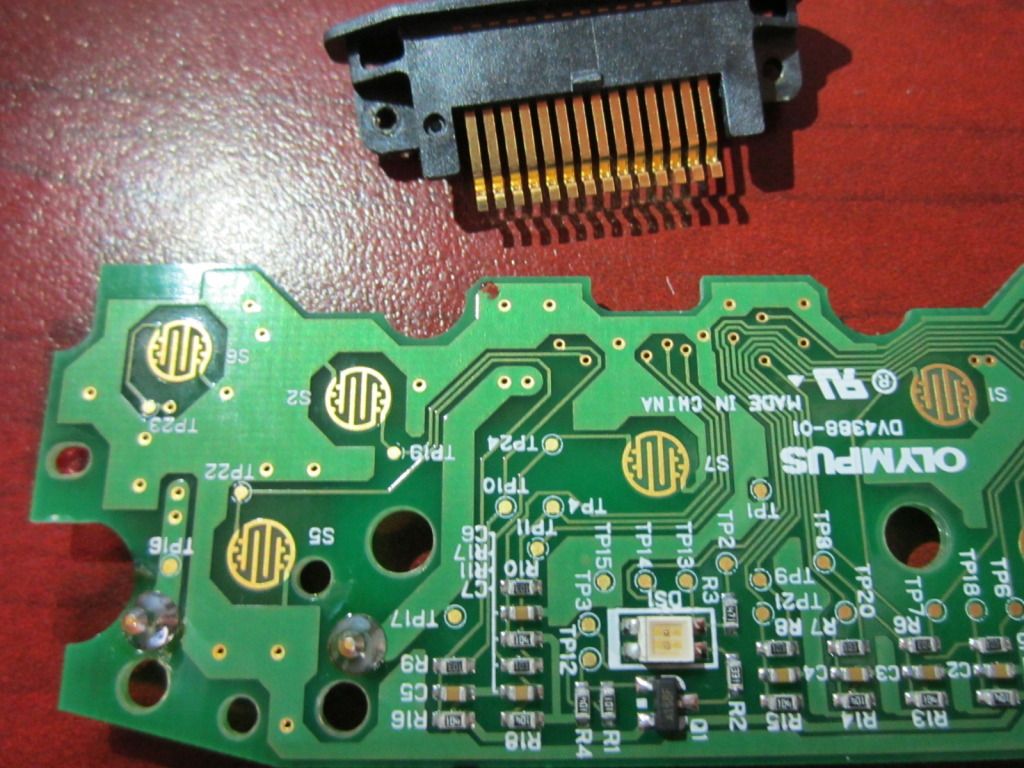

Also remember base metals in electronic components can be inside a component like layers of copper in between layers of fiberglass on multi-layer circuit boards, or under solder mask, or inside electronic packages like CPU's, if the acid reaches the metal and had gold in solution the gold could now be cemented inside these areas where you cannot see it anymore.

The stannous chloride test reduces values that are oxidized in solution the tin chloride gives electrons to the values, but also keeps them in solution as colorful colloids (colloids are metal particles that repel each other keeping each other in solution and not precipitating to the bottom of the vessel), the colorful reaction which help us determine if the metal we are looking for was in solution.

Very fine particles of gold like brown or black powdered elemental gold (like cemented gold) or very fine flakes of gold will normally settle to the bottom of a vessel, unless the solution is dirty with things like oils from your hands, dirty solutions from circuit boards oils heat sink grease, organic materials, or other nasty substances like tin from solder or a thick dirty copper chloride solution, these dirty solutions can hold fine elemental gold in solution, and the gold being a fine metal powder the stannous test will not detect it (the gold is already reduced, and stannous chloride cannot reduce it to the violet color).

Letting a solution settle the fine gold powder or flakes will normally settle, some floater can be sunk with a mist from a water spray bottle, and filtering solution may recover fine gold that is held in solution if there is any, but if tin (the gold could have formed colloids which will not settle) if the tin is involved then you may find even filtering almost impossible in this case the goop (if values involved) are best dehydrated, neutralized, rinsed, then dried, and incinerated, then the oxidized metal powder given a boil in HCl to help remove the tin.

Tin in nitric is impossible to filter, tin in HCl is not much better.

If you washed your material in HCl to dissolve the solder (tin will dissolve into solution), and, you did not use a strong oxidizer, then you did not dissolve gold, (some silver if involved in the solder along with lead will form insoluble white or gray chloride powders as the solder breaks down (these two metals can be separated with boiling hot water, lead chloride in hot water is somewhat soluble silver chloride is insoluble), the HCl alone without an oxidizer can help to remove some of the troubles discussed above concerning the tin in solution.