jimmyreece

Well-known member

when boiling hcl, can i seal the flask to keep fumes down or would it develop to much pressure ?

jimmyreece said:i need to get that hood built !

Are you thinking clearly? (No, I'm not trying to be rude!)jimmyreece said:no i wasnt going to do any evaperating, i was going to rid some base metals that are in a AuCL solution i need to clean. its quite a bit. i was just thinkn about cutting down on the fumes a little. i need to get that hood built !

Heh! No problem.jimmyreece said:after reading my own words....that does sound foolish. what i meant to say was i plan on boiling the powders in Hcl (after precipitation) from a dirty AuCL solution.

Thank you for correcting me

i failed to get(im guessing) all the copper out of the AuCl prior to Hcl+Cl dissolution. i say that because of the green color solution i ended up with after i added Cl.(is that common?) but like dtectr said, it could be a number of different base metals.

Heh! Matter of opinion, I guess. Most folks think I'm too pushy-----and narrow of mind. Typical of a guy with perfectionist tendencies. (Note I didn't say I was a perfectionist!)jimmyreece said:you would have made a great teacher.

anyway. no i hadnt planned on selling any of what little gold i have aquired since last january, just yet....ive worked way to hard and way to long to give up my little residual returns from a 1/2 dozen 1st attempt processes that easily.

no harold, im going to get good at this and when im finaly proud enough to take some pics. then maybe i will sell to get some returns back.

everything precipitated okay, tonight im going to decant and wash the gold real good several times. then run it through Hcl+Cl one more time

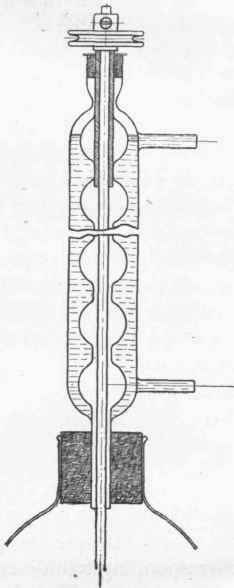

4metals said:At the end of the day, venting is more important than mixing, if you can't get a 2 necked flask, opt for venting.

Enter your email address to join: