jeneje

Well-known member

I need input on this design i made today before i test it in the morning. After thinking about the stupid remark i made to chickenhawk about using a wet cloth :roll: not smart at all and yes i do no better. I wanted to design something cheap that all members can afford to help with the NOx we make during the processing of base metals. Here is what i came up with and any suggestion welcome.

I went to walmart and got a one gallon ball mason jar made of glass cost 15.00 the top has a plastic seal and the cap is stainless. I then took two five gallons buckets, one i cut the botton off 2" down the side, so the main bucket will site down in it. Next i drilled an 11/16 hole in the side of the main bucket for the pvc piping to come through. Then i cut an hole in the top of the jar also for the piping to fit into.

I have posted the pictures of what it looks like and if it works i will post all the fitting and tools needed to make this but first i wanted to try so no one will get hurt.

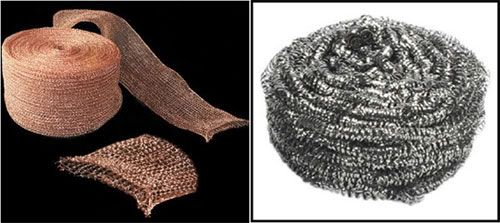

The main container will hold a lye solution for the NOx to bubble in as the pressure increases in the jar it should force the gas to the container. The top will have a heavy cloth on it and then i used one of my classifiers that will set down in the bucket to hold a packing bed. I will try it with charcoal first if it works i would recommend limestone chips or maybe wood ash.

Thanks in advance for any help.

Ken

I went to walmart and got a one gallon ball mason jar made of glass cost 15.00 the top has a plastic seal and the cap is stainless. I then took two five gallons buckets, one i cut the botton off 2" down the side, so the main bucket will site down in it. Next i drilled an 11/16 hole in the side of the main bucket for the pvc piping to come through. Then i cut an hole in the top of the jar also for the piping to fit into.

I have posted the pictures of what it looks like and if it works i will post all the fitting and tools needed to make this but first i wanted to try so no one will get hurt.

The main container will hold a lye solution for the NOx to bubble in as the pressure increases in the jar it should force the gas to the container. The top will have a heavy cloth on it and then i used one of my classifiers that will set down in the bucket to hold a packing bed. I will try it with charcoal first if it works i would recommend limestone chips or maybe wood ash.

Thanks in advance for any help.

Ken