Lobby

Well-known member

4metals said:...

Volumetric Silver Titration

“Volhard’s method”

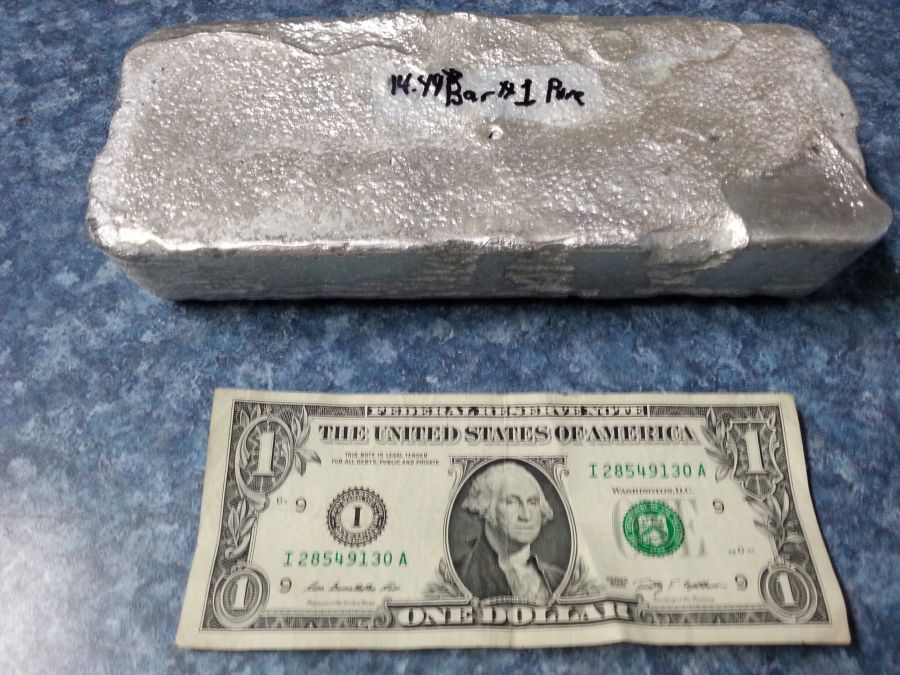

The analysis of silver bullion by titration is a very accurate for high silver bullion and fine silver. Samples which are soluble in nitric acid are perfect for this method. The converted silver chlorides from the aqua regia refining process also work well as the gold can be calculated gravimetrically after the parting process and the silver can be calculated via titration. This method eliminates cupellation and proofs required to correct for furnace losses. It also is preferred for fine silver assays providing the titrant is calibrated against fine silver when it is made up.

The basis of the reaction is as follows:

AgNO3 + KSCN = AgSCN + KNO3 (1)

3KSCN + Fe(NO3)3 = Fe(SCN)3 + 3KNO3 (2)

Reaction (2) does not occur until (1) is completed, therefore the addition of a small amount of a soluble ferric salt serves as an indicator by the formation of red ferric thiocyanate in the presence of an excess of the thiocyanate. When the titrant enters the solution it will produce a red streak which will re-dissolve on mixing until all of the silver has been converted and the solution turns red signifying the end point. Chlorides interfere by reaction with silver so all reagents, glassware, and water must be chloride free.

Potassium thiocyanate Prepare and standardize a solution. (M=N) 5 g KCNS Diluted to 1 L. Standardize against 0.5g fine silver.

Ferric alum indicator Dissolve 100g of crystals in 1 liter of distilled water, Add 2M Nitric Acid to clear the solution.

...

I'm in the process of setting up to do some Volhard titrations and have a question.

Rxn 2 shows the use of Ferric nitrate as the source of the iron indicator, but later in the procedure you mention ferric alum indicator: iron (III) ammonium sulfate.

I suppose all that's needed is a source of Fe, so it shouldn't matter what iron chemical is used. But before I purchased anything, I thought I'd ask.

Thanks, folks!