Had that statement been clarified to the processing of ultra pure elements I might have agreed with it, but electrolysis is used industry wide even today as a cheap effective way to separate metals. Both have their place, but to say it is a relic is far from the truth.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Silver Electrolytic Cell Volume

- Thread starter kadriver

- Start date

Help Support Gold Refining Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Research135

Well-known member

- Joined

- Jul 24, 2015

- Messages

- 90

You heard it here first!. hehe.Palladium said:Had that statement been clarified to the processing of ultra pure elements I might have agreed with it, but electrolysis is used industry wide even today as a cheap effective way to separate metals. Both have their place, but to say it is a relic is far from the truth.

Sputins

Member

- Joined

- Oct 28, 2014

- Messages

- 20

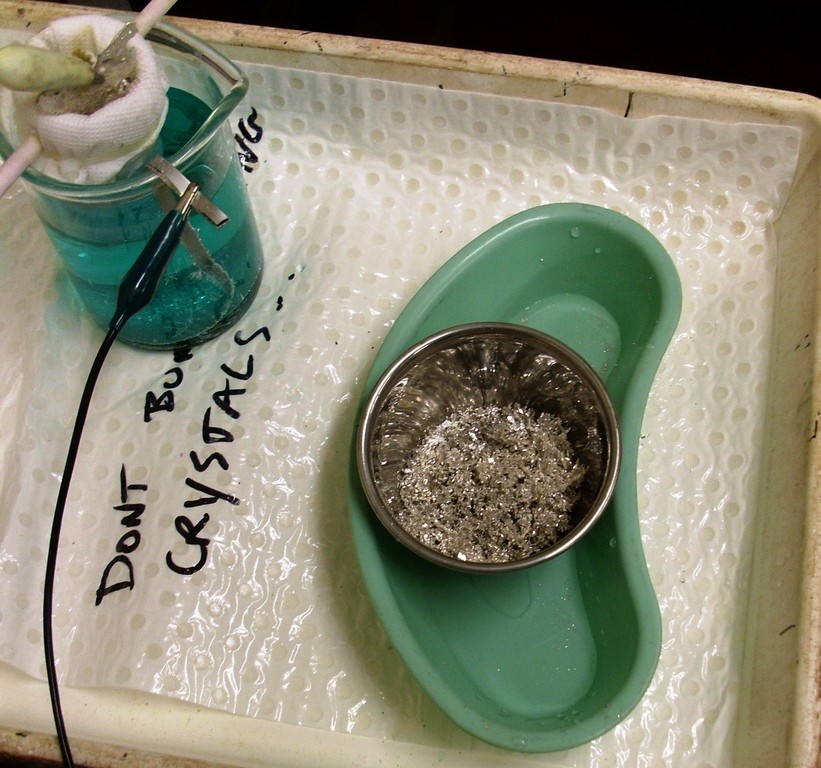

I’ve had my first go at the beaker sized 300ml silver cell, with 149mls of water, 149mls of Nitric Acid and 124.4g of silver (from cemented silver).

So there was a little copper in my silver as seen from the solution colour. Not too much though.

I adapted a PC power supply 3.3volts at 10amp max, with a 4 amp in-line fuse.

I tried using two layers of the Polypropylene pillow case protector material ($3 each) and it seems to work just fine.

Let the pictures speak!

Growing…

Just before the fuse blew due to short circuit...

Next batch…

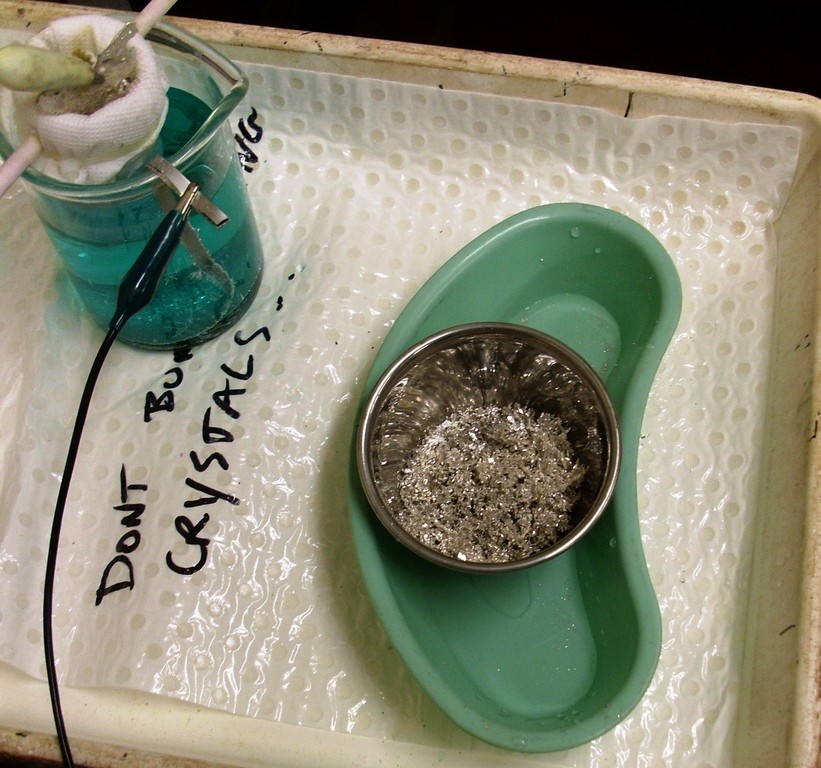

My first ever batch of glorious gleaming silver crystals! Only about 80 grams here.

I’ll keep making crystals until I have enough for the bigger silver cell of about 3Ltr capacity.

Thanks for all the advice and info found here on the GRF.

So there was a little copper in my silver as seen from the solution colour. Not too much though.

I adapted a PC power supply 3.3volts at 10amp max, with a 4 amp in-line fuse.

I tried using two layers of the Polypropylene pillow case protector material ($3 each) and it seems to work just fine.

Let the pictures speak!

Growing…

Just before the fuse blew due to short circuit...

Next batch…

My first ever batch of glorious gleaming silver crystals! Only about 80 grams here.

I’ll keep making crystals until I have enough for the bigger silver cell of about 3Ltr capacity.

Thanks for all the advice and info found here on the GRF.

Sputins

Member

- Joined

- Oct 28, 2014

- Messages

- 20

Palladium said:Looking good!

Thanks!

As seen I’ve copied the other silver cell designs seen here on the forum:

Below: my new electrolytic silver cell, the stainless steel bowl contains 600g of silver made up to 4 Liters. (150g/L) It’s all housed in a fume cupboard.

Below: With the cover off showing the silver crystals forming in the stainless steel bowl, this bowl seems great, the surface is so polished that the crystals forming around the brim get too heaver and simply slide off. This is after around 24 hours of running the cell, it consumed all of the silver shot in the anode bag, so I’ll have to add more silver shot. (It consumes it faster than I can produce the shot).

Below: Close up of the crystals in the bowl. These are not as dense as with the beaker because the electrolyte is less concentrated than with the saturated solution with the beaker. As you guys would know, the camera fails to pick up the full shininess of these crystals. To the eye these look spectacular!

Below: Anode basket and filter. The filter material used is polypropylene pillow case protector material. Probably the basket is too big, I might make a smaller one to fit inside it.

Hi

From reading the silver cell text that Steve posted, I see:

Electrolyte 12 to 12.5 grams of silver nitrate per 100 mL of distilled water or

75 to 100 grams per liter of silver

So if I have 1 liter electrolyte I must have maximum 100 gram silver in it. But it contains silver in the basket too ?

In other words I must have for example 50 gram silver in electrolyte and 50 gram in anode basket?

Thanks

From reading the silver cell text that Steve posted, I see:

Electrolyte 12 to 12.5 grams of silver nitrate per 100 mL of distilled water or

75 to 100 grams per liter of silver

So if I have 1 liter electrolyte I must have maximum 100 gram silver in it. But it contains silver in the basket too ?

In other words I must have for example 50 gram silver in electrolyte and 50 gram in anode basket?

Thanks

Saadat,

The concentration of silver in the electrolyte is kept as constant as possible, the weight of silver in the anode basket will constantly be digested and pure silver will deposit at the cathode. When the instructions speak of a concentration of silver in grams per liter that is the concentration in the electrolyte solution. The weight of silver in the basket doesn't matter, you need surface area of anodes to dissolve so you keep adding as the anode basket silver goes down. The trick is to analyze the bath for silver because if you are processing sterling silver the copper will climb and the amount of silver in solution tends to drop.

The concentration of silver in the electrolyte is kept as constant as possible, the weight of silver in the anode basket will constantly be digested and pure silver will deposit at the cathode. When the instructions speak of a concentration of silver in grams per liter that is the concentration in the electrolyte solution. The weight of silver in the basket doesn't matter, you need surface area of anodes to dissolve so you keep adding as the anode basket silver goes down. The trick is to analyze the bath for silver because if you are processing sterling silver the copper will climb and the amount of silver in solution tends to drop.

Basically it is right but the cement silver needs to be melted into anodes, you cannot use powdered cement silver.

The silver will drop in concentration as the copper increases. For a small use it for a single lot of silver sized cell (like the ones described here with a stainless pot for the cathode) you usually run out of silver before the copper gets too high. But after copper gets above 60-70 grams per liter it starts to plate out with the silver.

So if you are going to produce a lot of silver in a production cell, you need to learn to titrate the silver concentration to control the cell.

Buy and read Goldsilverpro's book, it is worth it he has an entire section on silver cells and the titration.

GoldSilverPro's eBook For Sale.http://goldrefiningforum.com/phpBB3/viewtopic.php?f=84&t=22327&p=233617#p233617

The silver will drop in concentration as the copper increases. For a small use it for a single lot of silver sized cell (like the ones described here with a stainless pot for the cathode) you usually run out of silver before the copper gets too high. But after copper gets above 60-70 grams per liter it starts to plate out with the silver.

So if you are going to produce a lot of silver in a production cell, you need to learn to titrate the silver concentration to control the cell.

Buy and read Goldsilverpro's book, it is worth it he has an entire section on silver cells and the titration.

GoldSilverPro's eBook For Sale.http://goldrefiningforum.com/phpBB3/viewtopic.php?f=84&t=22327&p=233617#p233617

Latest posts

-

-

-

-

-

-

Trade Where can I sell calaverite ore(contains 3~7kg of gold per ton)?

- Latest: Dsrazstuntdriver