Hi everyone!

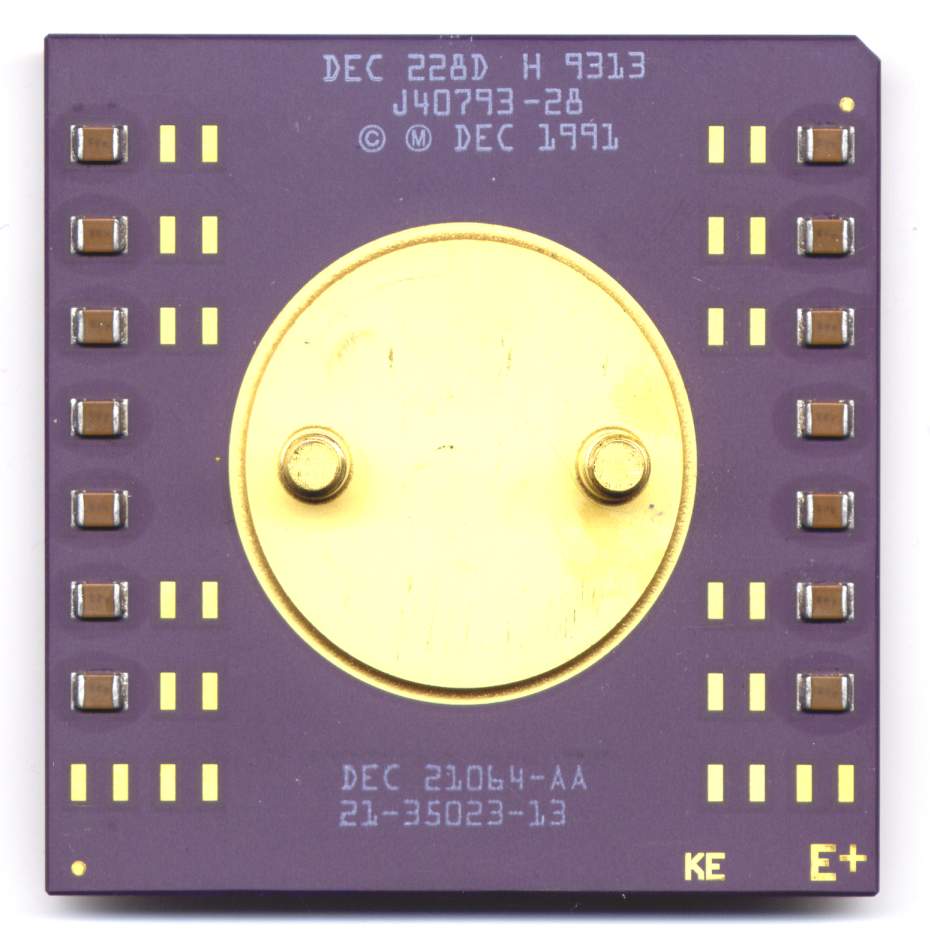

I was thinking of recovering the gold from my ceramic cpu box for the next learning experience. The picture is the family sitting around the porch with my cpu collection.I think the other twin cut off some of the collection at the bottom so he could get his brother in the picture.

Im in the process of breaking up the ceramics, most of the gold plated heat spreaders break up along with the ceramic, so did alot of the small chip in the center.

As I was studying I ran across gold n scrap's video where he dissolves everything in AR and then drops the gold from the dirty solution. I was wondering if I would be better off to heat the material in a dilute nitric bath first to remove as much of the base metals as posible and then run the AR. Or I could run an AP bath before going to the AR.

I still have to do some searching about the presents of tin. Most of the solder or brazing apears to be gold. Afew have a silver colored braze. I'm going to see if AP solution I dropped on some of the silver braze reacts when I get home. A question! If there is a reaction, and I put a small piece of the material with the silver solder in HCl,if there is tin in the solder It should turn purple if I add a drop of my auric chloride solution? Thanks for any advice or links that would be helpfull!

Will weigh it up after I finish breaking them. It's about ten pounds. I post my progress!

excited! artart47

I was thinking of recovering the gold from my ceramic cpu box for the next learning experience. The picture is the family sitting around the porch with my cpu collection.I think the other twin cut off some of the collection at the bottom so he could get his brother in the picture.

Im in the process of breaking up the ceramics, most of the gold plated heat spreaders break up along with the ceramic, so did alot of the small chip in the center.

As I was studying I ran across gold n scrap's video where he dissolves everything in AR and then drops the gold from the dirty solution. I was wondering if I would be better off to heat the material in a dilute nitric bath first to remove as much of the base metals as posible and then run the AR. Or I could run an AP bath before going to the AR.

I still have to do some searching about the presents of tin. Most of the solder or brazing apears to be gold. Afew have a silver colored braze. I'm going to see if AP solution I dropped on some of the silver braze reacts when I get home. A question! If there is a reaction, and I put a small piece of the material with the silver solder in HCl,if there is tin in the solder It should turn purple if I add a drop of my auric chloride solution? Thanks for any advice or links that would be helpfull!

Will weigh it up after I finish breaking them. It's about ten pounds. I post my progress!

excited! artart47