You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Aqua Regia method with 12-13% Ag _inquart_

- Thread starter giahylxag

- Start date

Help Support Gold Refining Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

giahylxag

Well-known member

Just did my first test yesterday

My input is a small 7.5gr gold bracelet, with 60%Au, 13%Ag and 26%Cu.

1) Unexpectations

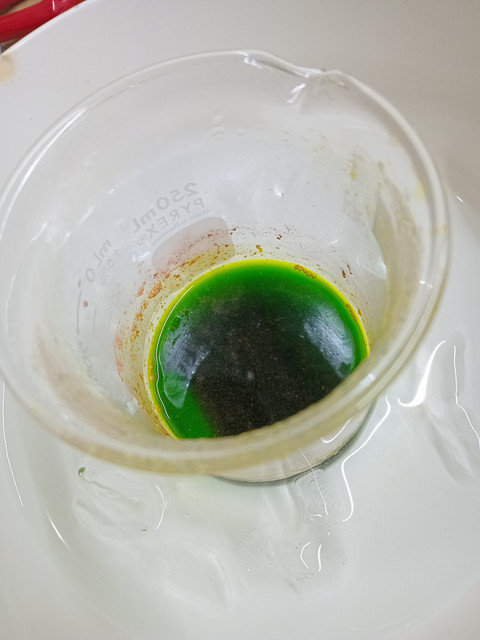

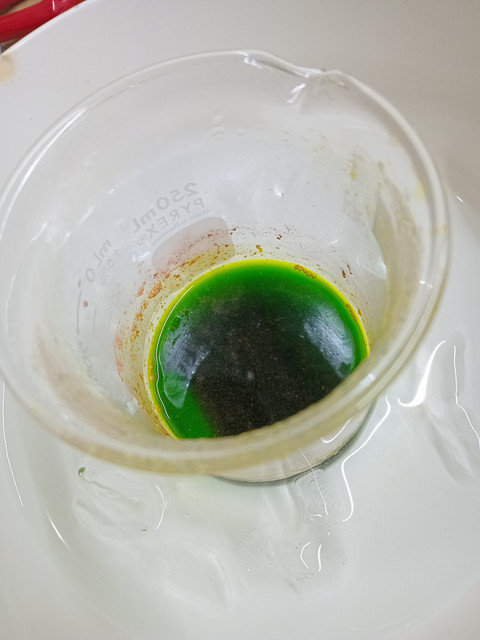

Instead a orange/yellow AR liquid. I got a strage yellowish-dark-green mud with some orange-looking residue on the wall of my becher

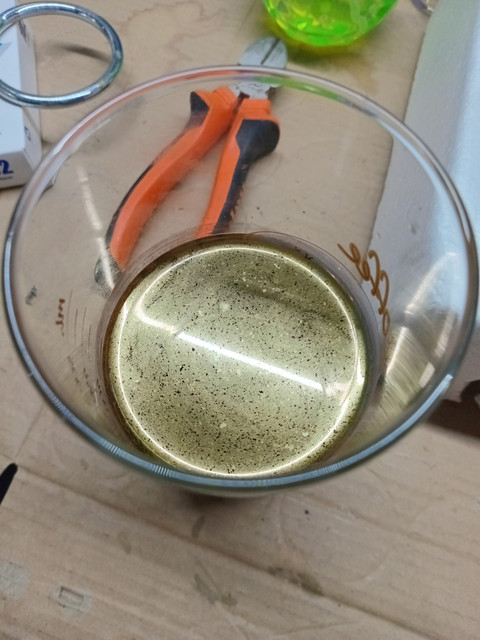

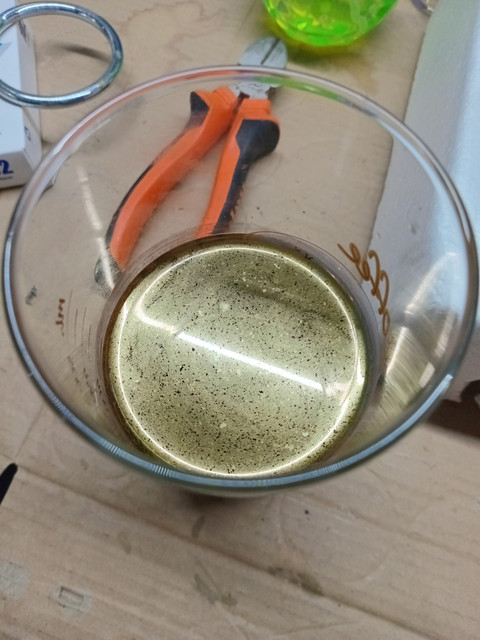

There is a sand-like black recipitation product that I believe is AgCl (but after the first filter it turned out to be gray, not black)

2) Drop gold using SMB

I use SMB to drop gold, I calculated I have around 6gr of pure gold so I add 6gr of SMB, but it seems not enough. Also, there is a very thin layer of gold on the surface but I don't know why.

There is also a black floating cloud that I have no idea also

I add more SMB and the liquid is much cleaner now. So everything seems Okay to this point.

Don't know if I lost some gold somewhere or I can reach 99+%Au or not

My input is a small 7.5gr gold bracelet, with 60%Au, 13%Ag and 26%Cu.

1) Unexpectations

Instead a orange/yellow AR liquid. I got a strage yellowish-dark-green mud with some orange-looking residue on the wall of my becher

There is a sand-like black recipitation product that I believe is AgCl (but after the first filter it turned out to be gray, not black)

2) Drop gold using SMB

I use SMB to drop gold, I calculated I have around 6gr of pure gold so I add 6gr of SMB, but it seems not enough. Also, there is a very thin layer of gold on the surface but I don't know why.

There is also a black floating cloud that I have no idea also

I add more SMB and the liquid is much cleaner now. So everything seems Okay to this point.

Don't know if I lost some gold somewhere or I can reach 99+%Au or not

Last edited:

The green is from the Copper.

Did you roast the bracelet first?

Separate the clasps and such?

giahylxag

Well-known member

Just update more pictures. No I did not roast it first. Maybe there are alot of dirt there. Also the bracelet is more like a bangle so there is not many parts to seperateThe green is from the Copper.

Did you roast the bracelet first?

Separate the clasps and such?

I see you have decided to start with the aqua regia approach as the result of your heated discussion with your chemist friend.

Apparently the 13% Silver is too high to effect a complete dissolution and you do have encapsulated gold that has not dissolved. That gold is now coated with a dark green yellowish coating which is what the residue of gold alloy coated with Silver Chloride looks like when it is not completely rinsed.

The dark colored acid is from the copper as pointed out.

You will not, in the end when it is dried and melted, recover all of the gold. A percentage is tied up in chlorides and since you did not have the benefit of tumbling that percentage will be higher than it would be if you tumbled.

,

For this experiment to convince you and your aqua regia inclined friend you should now take a sample of similar size, inquart it, and part it in nitric. You will then, with proper parting have >99% gold after rinsing which, when refined in aqua regia, will produce a nice red - orange acid after the reaction and will yield a very high purity gold.

Try the inquarting, you will come back completely converted to an inquart man. Then your chemist friend owes you a beer!

Apparently the 13% Silver is too high to effect a complete dissolution and you do have encapsulated gold that has not dissolved. That gold is now coated with a dark green yellowish coating which is what the residue of gold alloy coated with Silver Chloride looks like when it is not completely rinsed.

The dark colored acid is from the copper as pointed out.

You will not, in the end when it is dried and melted, recover all of the gold. A percentage is tied up in chlorides and since you did not have the benefit of tumbling that percentage will be higher than it would be if you tumbled.

,

For this experiment to convince you and your aqua regia inclined friend you should now take a sample of similar size, inquart it, and part it in nitric. You will then, with proper parting have >99% gold after rinsing which, when refined in aqua regia, will produce a nice red - orange acid after the reaction and will yield a very high purity gold.

Try the inquarting, you will come back completely converted to an inquart man. Then your chemist friend owes you a beer!

giahylxag

Well-known member

Luckily the sample size is very small (7.5g) so gold loss is not considerable.I see you have decided to start with the aqua regia approach as the result of your heated discussion with your chemist friend.

Apparently the 13% Silver is too high to effect a complete dissolution and you do have encapsulated gold that has not dissolved. That gold is now coated with a dark green yellowish coating which is what the residue of gold alloy coated with Silver Chloride looks like when it is not completely rinsed.

The dark colored acid is from the copper as pointed out.

You will not, in the end when it is dried and melted, recover all of the gold. A percentage is tied up in chlorides and since you did not have the benefit of tumbling that percentage will be higher than it would be if you tumbled.

,

For this experiment to convince you and your aqua regia inclined friend you should now take a sample of similar size, inquart it, and part it in nitric. You will then, with proper parting have >99% gold after rinsing which, when refined in aqua regia, will produce a nice red - orange acid after the reaction and will yield a very high purity gold.

Try the inquarting, you will come back completely converted to an inquart man. Then your chemist friend owes you a beer!

Next question is why there is a very thin layer of gold on the surface when I drop SMB in? Is it supposed to be sand-like and brown and drop down to the bottom?

$80.52

$115.00

Petroleum Refining: Technology, Economics, and Markets, Sixth Edition

Woodville Books

$248.83

The Extraction and Refining of Metals (Materials Science & Technology Book 2)

Amazon.com Services LLC

$18.39

Moneysworth & Best Brillo Nu-Life Leather/Vinyl/Plastic Color Renew Spray 4.5 oz, 024 Gold

Shoe and Boot Accessories 4 U

$21.99 ($3.14 / Count)

WORKPRO 7-Piece Jewelers Pliers Set, Jewelry Making Tools Kit with Easy Carrying Pouch (Blue)

GreatStar Tools

$245.67 ($0.06 / Ounce)

50 lb Sodium Nitrate Fertilizer 99+% Pure Chile Saltpeter Gold Metal Refining Industrial Grade Glass Pottery Enamels

Duda Energy

$153.25

$200.00

Hydrotreating and Hydrocracking Processes in Refining Technology (Petroleum Refining Technology Series)

Prime Deals, USA

$29.64

$33.00

JSP 12 Bottles 22k Gold Metal Test Acid Karat Testing Liquid Solution Jewelry Teste

BasaRetail

$123.78

JOMRTS Electrical Panel Cover Flip UP Circuit Breaker Box Cover Decorative Wall, Wall Hole Cover Decorative Box for Electrical Box (Gold Frame 11.8x15.7In)

JiNanYunShiAnShangMaoYouXianGongSi

$6.99 ($0.14 / Count)

$7.99 ($0.16 / Count)

Beauticom 3g/3ml (0.1 Fl Oz) Round Clear Plastic Jars with Round Top Lids for Creams, Lotions, Powders, Glitters, and more... (Color: Clear Lid, Quantity: 50 Pieces)

Beauticom

There are many kinds of reactions going on and some of the Gold might attach itself to fatty substances and other dirty stuff and float.Luckily the sample size is very small (7.5g) so gold loss is not considerable.

Next question is why there is a very thin layer of gold on the surface when I drop SMB in? Is it supposed to be sand-like and brown and drop down to the bottom?

Did you filter the solution before you processed it further? You also did not mention any method you used to deal with the free nitric acid. If metabisulfite is used and there is free nitric acid the reaction of precipitating the Gold and the redissolving of the Gold often takes place floating on the surface in dirty or improperly filtered solutions.

Done right the gold dropped is heavy and sinks easily.

Done right the gold dropped is heavy and sinks easily.

giahylxag

Well-known member

Yes I did filter it, I filtered out all the AgCl (maybe some gold in it, too).Did you filter the solution before you processed it further? You also did not mention any method you used to deal with the free nitric acid. If metabisulfite is used and there is free nitric acid the reaction of precipitating the Gold and the redissolving of the Gold often takes place floating on the surface in dirty or improperly filtered solutions.

Done right the gold dropped is heavy and sinks easily.

About the free nitric, I just boiled it for some time, dropped a little ure and saw no reaction.

For this particular test, things work fine at the moment, the gold dropped, the solution is very clear, the thin gold layer is gone. I will update pictures tomorrow

But I use at least double the amount of SMB (in weight) compared to my gold.

giahylxag

Well-known member

I am very careful with my tools and glasswares. But I didn't roast the bangle first, maybe that was the problem, it was dirtyThere are many kinds of reactions going on and some of the Gold might attach itself to fatty substances and other dirty stuff and float.

Boiling will do nothing to the Nitric.Yes I did filter it, I filtered out all the AgCl (maybe some gold in it, too).

About the free nitric, I just boiled it for some time, dropped a little ure and saw no reaction.

For this particular test, things work fine at the moment, the gold dropped, the solution is very clear, the thin gold layer is gone. I will update pictures tomorrow

But I use at least double the amount of SMB (in weight) compared to my gold.

And Urea is not complete and can create dangerous compounds.

The two best methods is not use too much Nitric or use Sulfamic acid.

I have processed a lot of chemical stone removal where the jewelry is digested as it is received. You cannot heat it to red heat to burn off any oils because it will ruin the stones. As a result the reaction occasionally had a golden film on the acid from the oils holding small particles. Usually the prolonged hot aqua regia reaction was enough to take care of the problem, but they were larger lots. Small refining lots are the most difficult to do properly because you are looking for so little gold and the solutions are dilute.

giahylxag

Well-known member

Update

I calculated there must be at least 4 gram of pure gold but i recieved just 2 gram. Look like I made a big mistake. I burned the filter paper by a torch and the ash just flying around. Or a lot of gold is trapped in the AgCl

I calculated there must be at least 4 gram of pure gold but i recieved just 2 gram. Look like I made a big mistake. I burned the filter paper by a torch and the ash just flying around. Or a lot of gold is trapped in the AgCl

Both is most likely true.Update

I calculated there must be at least 4 gram of pure gold but i recieved just 2 gram. Look like I made a big mistake. I burned the filter paper by a torch and the ash just flying around. Or a lot of gold is trapped in the AgCl

If you want to have good accountability.

You will need to have good process control and good lab procedures.

With chemical / wet refining your loses will be much higher by percentage in small lots as opposed to larger lots if you process properly and carefully and stone set material is not easy to get a decent return due to mixed alloys / karats that do not fully dissolve .

Most processing loses are recoverable some time later when time and quantity make recovery worthwhile.

Most processing loses are recoverable some time later when time and quantity make recovery worthwhile.

giahylxag

Well-known member

How to properly burn the filter paper and get the gold. I don't think the torch is okay, many vids I have seen on youtube they just straight burn it by a torch (streetips guy for example).Both is most likely true.

If you want to have good accountability.

You will need to have good process control and good lab procedures.

That will be filters with Gold metal powder in it, not "Dirty" filters with chlorides and such.How to properly burn the filter paper and get the gold. I don't think the torch is okay, many vids I have seen on youtube they just straight burn it by a torch (streetips guy for example).

If you are properly ashing paper it should be heated to around 300-500 degrees C and combust by itself in open air.

If we are talking of Filters as Sreetips do in videos, they are cleaned Gold metal and can be heated and melted directly.

You need to keep focus on the details.

giahylxag

Well-known member

I did use the cleaned gold filter and I was talking about it. But the the filter paper created ash and shot itself aroundThat will be filters with Gold metal powder in it, not "Dirty" filters with chlorides and such.

If you are properly ashing paper it should be heated to around 300-500 degrees C and combust by itself in open air.

If we are talking of Filters as Sreetips do in videos, they are cleaned Gold metal and can be heated and melted directly.

You need to keep focus on the details.

I used Whatman filter

If it is Gold metal there should not be losses by the ash.I did use the cleaned gold filter and I was talking about it. But the the filter paper created ash and shot itself around

But proper filter paper usually create very little ash.

Ignition it and let it burn, then start heating the powder until it melt.

Watch Sreetips/Kadriver until you understand.