nicknitro

Well-known member

Hello All,

Quick question regarding some scraps I recently came into.

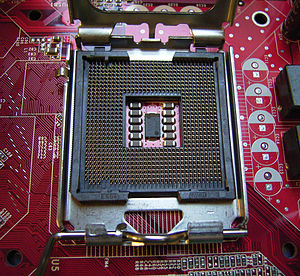

The Material I had a question about is the bridge connector/ cradle, that holds and connects CPU's with no pins to the board. Similar to slotted Intel processors. In most of these modules the connectors were gold colored, and relatively loose fitting, as I could scrape them out by rubbing my finger across them. Sorry no pictures, I will try to upload some, I just figured someone has probably dealt with these types of materials before. Incidently, in one of the modules, the connector legs are a white-ish color. Haven't touched it yet. Don't have much experience with it if it is what I think it is. Pd?

Anyways, I put some of the gold colored ones in a small test batch of 10 K test kit "nitric only". Nothing had really happened. So I kinda jumped the gun and skipped up to the 18K test solution. After a short while, I came back and the connectors had dissolved. Here's the weird part, they kinda turned a dark reddish-brown color. I don't want to say Kovar, cause wouldn't the nitric have dissolved it pretty quickly, unless the plateing were pretty thick, and locked the kovar in away from the HNO3.

I did not get a chance to test with stannous, again I guess I jumped the gun and just assumed gold to be a component in this type of material.

Steve, anyone, in your endeavors in E-Scrap have you run into materials like these?

Much Appreciated,

Nick

Quick question regarding some scraps I recently came into.

The Material I had a question about is the bridge connector/ cradle, that holds and connects CPU's with no pins to the board. Similar to slotted Intel processors. In most of these modules the connectors were gold colored, and relatively loose fitting, as I could scrape them out by rubbing my finger across them. Sorry no pictures, I will try to upload some, I just figured someone has probably dealt with these types of materials before. Incidently, in one of the modules, the connector legs are a white-ish color. Haven't touched it yet. Don't have much experience with it if it is what I think it is. Pd?

Anyways, I put some of the gold colored ones in a small test batch of 10 K test kit "nitric only". Nothing had really happened. So I kinda jumped the gun and skipped up to the 18K test solution. After a short while, I came back and the connectors had dissolved. Here's the weird part, they kinda turned a dark reddish-brown color. I don't want to say Kovar, cause wouldn't the nitric have dissolved it pretty quickly, unless the plateing were pretty thick, and locked the kovar in away from the HNO3.

I did not get a chance to test with stannous, again I guess I jumped the gun and just assumed gold to be a component in this type of material.

Steve, anyone, in your endeavors in E-Scrap have you run into materials like these?

Much Appreciated,

Nick