rich_2137

Well-known member

Hi all

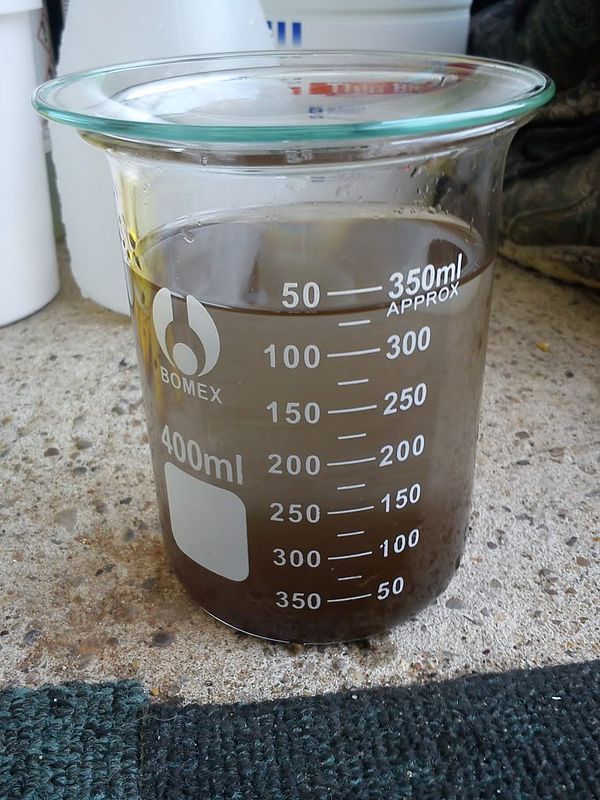

I've just brought some jewellers pure gold dust and processed it with AR and the solution has turned green, the last time I used AR on pure gold powder the solution was orange, have I been stung?

Rich

I've just brought some jewellers pure gold dust and processed it with AR and the solution has turned green, the last time I used AR on pure gold powder the solution was orange, have I been stung?

Rich