I must say, I am a tad puzzled by your rig. Perhaps it is the difference in format between US & Euro rigs if you are in Europe.

No way should you have a 4-5 foot long flame. No way at all. That is completely out of control. Something is not right. You must be feeding gargantuanly too much fuel to the thing. I am at this moment skeptical that one could adjust the flame to that size even if they wanted to, that is so much fuel that I am surprised the flame can even sustain itself without blowing out.

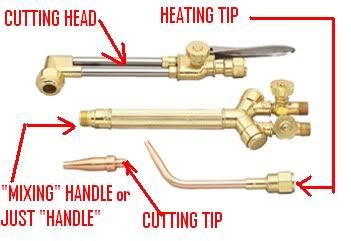

This is the normal configuration of how an oxyacetylene "kit" would come in the US. You would have more, different sized heating tips, but they would would all look about the same.

To weld, you screw a heating tip onto the mixing handle. You just open the fuel tank valve a little: more than just a crack but not full on. You adjust your fuel regulator to about 4-6 lbs of acetylene. With propane, probably around 6-8 lbs. Whenever you adjust your regulator outputs, you have to have the torch valves open so that excess pressure of either gas can escape, or, underpressure can fill the lines and the torch without backpresssure. Thus, a little gas escapes. The regulator pressure adjust procedure should start by unscrewing the big knob so that it feels a little loose. That corresponds to zero output. With the fuel tank valve a little bit open and the torch-handle fuel valve somewhat open you turn the reg knob clockwise and you will feel it get a touch harder to turn at some point. Only a little bit after you feel it get harder to turn, keep turning clockwise, and the low pressure gauge should start showing 1-2-4 lbs of pressure and that's where you want it for acet, maybe 6-8 lbs for propane. You will dial this in a little now and again as the amount of fuel in your tanks is drawn down, but in essence, you will never touch this again. You leave it where you like it and turn on and off your welding operation using the valves on the handle and the tank. Once you have 6-8 lbs at the torch end as indicated by the regulator, shut off the fuel valve at the torch handle. You haven't ignited anything, you are just checking fuel flow.

Now you move to the oxy cylinder. Start by unscrewing counterclockwise the regulator adjust knob to that loose condition. That is zero output. Make sure your face is nowhere near the glass faces of the regulators, turn your head away, and crack open the oxy valve.

Remember that there are thousands of lbs of pressure in the oxy cylinder and if the regulator fails and blows out the glass faces of the gauges, they'll embed into your skull. So when you open up Mr. Oxy, your face and head are out of picture. Once cracked open, the oxy valve is a different type than the fuel valve, is a double-packed valve, and should be opened all the way, slightly snug against the stop in the open position. In practice, most people do not do this, they just open the valve some, but it is the correct practice to open it all the way against the "open" stop.

Now you do the same thing as with the fuel. Open up the oxy valve on the torch handle some. Start turning the oxy regulator until you feel slight resistance, and you'll see the low pressure gauge on the regulator get to 4-6-8 lbs. Close the torch handle oxy valve.

Now, your regulators are set to 4-4 or 6-6 or 8-8, pretty much matched oxy and fuel pressure and you are ready to WELD or BRAZE. (Not cut steel)

You screw the heating tip of your choice on to the mixing handle, turn on fuel, light up fuel, adjust, turn on oxy, adjust, get your flame where you like it, and start to burn metal.

^^^^^^^^^^^^^^^

Now NewBullion, I have two comments on your rig.

First, it appears to me that what you have is a DEDICATED cutting torch. I say that because you have that lever handle, and furthermore, that lever handle is way back on the body of the torch. You will note that on your typical welding-cutting outfit I have pictured, there is a mixing handle that does not become a cutting handle UNTIL the attachment with that lever is attached to it. That big lever is characteristic of the cutting head, or a cutting torch. That lever opens a valve and lets high-pressure oxygen out at full blast to impinge on steel you have already heated red-hot. The full-blast oxygen chemically oxidizes the steel you wish to cut into slag and physically blows it away.

On the set I have pictured, you will note that the cutting head has 1: the lever to open the hi-pressure oxygen, and 2: another valve. That valve controls the hi-pressure oxygen flow. The hi-pressure oxygen pressure is in the neighborhood of 20-25 lbs. When using the style of rig I have pictured, IN ORDER TO CUT, you crank the oxygen pressure up to 20-25 lbs AT THE REGULATOR. The oxy valve that you just opened a little to WELD WITH when your pressure was 4-6-8 oxy you OPEN ALL THE WAY. Then, you use the valve on the cutting head more as a CHOKE...and turn down the oxy flow at the cutting head valve to produce your low-temp flame. You heat up (it's called pre-heat) the steel you wish to cut until red heat. When you depress the lever, oxy is turned on full blast and away you go.

So when I look at your rig which I am not familiar with, I do not see any "third" valve. This leads me to believe you have a dedicated cutting torch there. I myself do not think you want this type of setup.

Secondly, the type of tip attached to the torch end of your rig is a pre-heating or rosebud type of tip. A rosebud tip should go on the normal 2-handle mixing handle and, while it is typically a bigger and thicker tip than a normal cutting tip, it's just a bigger, 2-valve tip and has NOTHING to do with cutting. No third valve, no lever. Indeed, it surprises me somewhat that you can even screw such a rosebud tip onto your dedicated-cutting handle. It looks odd to me.

So I am really quite baffled by what you got going there. If I may say so. You might have a rig that is suitable to melting a kilo of silver at a time, but by the time you are melting that much silver, I don't think torch would be the method I'd use.

A cutting head (and I wouldn't be using that at all) should produce an inner cone, light blue flame between 1/4" and 3/4" long measured from the end of the tip, and a darker, outer, "feather" flame about 5-8" long. Depress the lever and the flame should get a lot noisier with the rush of full-blast oxygen, the inner cone goes away, and the whole flame turns lighter blue and maybe gets to be a foot long. But no way 4 feet. That is big time wrong.