You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

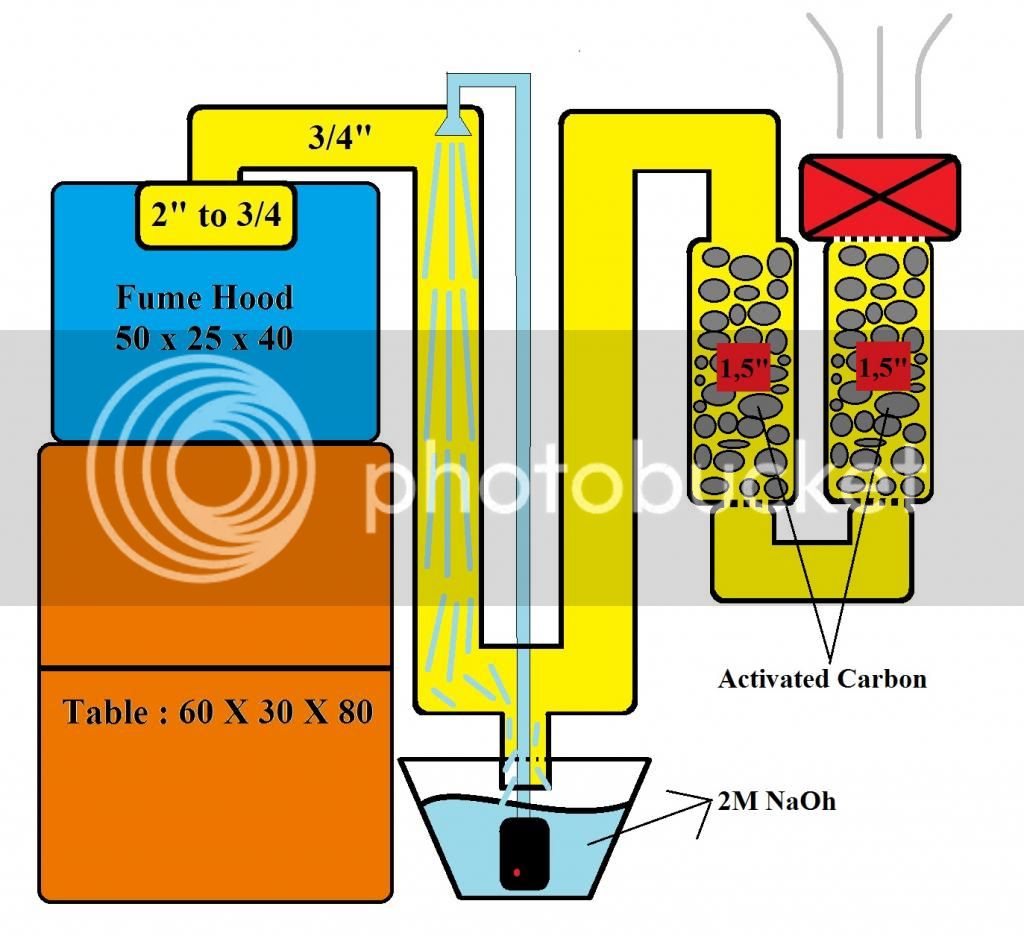

Scrubber Sketch, any reccomendation/ better Idea?

- Thread starter Wookie

- Start date

Help Support Gold Refining Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

NobleMetalWorks

Well-known member

Interesting design...

I think rather than making this a fume scrubber for your fume hood, you should change the design so that you can use it with sealed/enclosed reaction system. You are not going to provide enough suction to create positive air flow at the face of the fume hood. NOx gases are heavier than air, so if you do not have enough positive air flow the gasses will sink to the bottom of the inside of your fume hood, and then seek the lowest point and the only point of escape which would be to escape out of the front of your fume hood. An enclosed reaction system would create pressure which would force the gases into your fume scrubbing system. Even at that it might not create enough pressure to push the gases up to your spray down tube. To create enough suction you would want to use a venturi system. 4Metals has a really good design of one on this forum.

A condenser between your reaction vessel and the exit point from your fume scrubber will condense much of the gases back into solution that will then make it's way back into your reaction vessel. This cuts down on the amount of gas that needs to be processed by your fume scrubbing.

I would make the spray down tube drop directly into the water reservoir.

The gases will only interact with the very surface of the water, so I would pack the spray down stack with some sort of media that water droplets can cling to, thus creating more wet surface to collect gasses.

Your reservoir should have an access port large enough to exchange solution and clean it.

The reservoir would also benefit by the installation of an ORP meter so that you know when you need to change out the solution.

A chemical resistant pump, rated for alkali and acidic solutions, in your reservoir, will allow you to easily exchange solutions

Depending on your intentions, you might want to collect the solution as it would be weak nitric acid. In my own design I recover as much of the dilute nitric acid as possible and use it for leaching.

You need a way to monitor the activated carbon, after it becomes saturated and no longer can absorb pollutants, the pollutants will simply just pass right through it. A PH meter between the first and second activated carbon chambers, and after the second, will tell you when the first becomes saturated and needs replacement. In that particular design the secondary activated carbon chamber acts as a safety. If you find that they both are working at the same rate you will then know you should add more activated carbon chambers. A PH meter will also tell you if you are exhausting any NOx. You can even use PH strips on the exhaust to see if they change color and know if you are exhausting NOx.

That's just off the top of my head. There is several posts on fume scrubbers. You might want to look up 4Metals posts on the subject as he has talked about it extensively and has provided plans as well.

Scott

EDITED:

Here is the thread on 4Metals design:

http://www.goldrefiningforum.com/phpBB3/viewtopic.php?f=40&t=9115&hilit=4metals+wet+fume+scrubbing

I think rather than making this a fume scrubber for your fume hood, you should change the design so that you can use it with sealed/enclosed reaction system. You are not going to provide enough suction to create positive air flow at the face of the fume hood. NOx gases are heavier than air, so if you do not have enough positive air flow the gasses will sink to the bottom of the inside of your fume hood, and then seek the lowest point and the only point of escape which would be to escape out of the front of your fume hood. An enclosed reaction system would create pressure which would force the gases into your fume scrubbing system. Even at that it might not create enough pressure to push the gases up to your spray down tube. To create enough suction you would want to use a venturi system. 4Metals has a really good design of one on this forum.

A condenser between your reaction vessel and the exit point from your fume scrubber will condense much of the gases back into solution that will then make it's way back into your reaction vessel. This cuts down on the amount of gas that needs to be processed by your fume scrubbing.

I would make the spray down tube drop directly into the water reservoir.

The gases will only interact with the very surface of the water, so I would pack the spray down stack with some sort of media that water droplets can cling to, thus creating more wet surface to collect gasses.

Your reservoir should have an access port large enough to exchange solution and clean it.

The reservoir would also benefit by the installation of an ORP meter so that you know when you need to change out the solution.

A chemical resistant pump, rated for alkali and acidic solutions, in your reservoir, will allow you to easily exchange solutions

Depending on your intentions, you might want to collect the solution as it would be weak nitric acid. In my own design I recover as much of the dilute nitric acid as possible and use it for leaching.

You need a way to monitor the activated carbon, after it becomes saturated and no longer can absorb pollutants, the pollutants will simply just pass right through it. A PH meter between the first and second activated carbon chambers, and after the second, will tell you when the first becomes saturated and needs replacement. In that particular design the secondary activated carbon chamber acts as a safety. If you find that they both are working at the same rate you will then know you should add more activated carbon chambers. A PH meter will also tell you if you are exhausting any NOx. You can even use PH strips on the exhaust to see if they change color and know if you are exhausting NOx.

That's just off the top of my head. There is several posts on fume scrubbers. You might want to look up 4Metals posts on the subject as he has talked about it extensively and has provided plans as well.

Scott

EDITED:

Here is the thread on 4Metals design:

http://www.goldrefiningforum.com/phpBB3/viewtopic.php?f=40&t=9115&hilit=4metals+wet+fume+scrubbing

NobleMetalWorks said:Interesting design...

I think rather than making this a fume scrubber for your fume hood, you should change the design so that you can use it with sealed/enclosed reaction system. You are not going to provide enough suction to create positive air flow at the face of the fume hood. NOx gases are heavier than air, so if you do not have enough positive air flow the gasses will sink to the bottom of the inside of your fume hood, and then seek the lowest point and the only point of escape which would be to escape out of the front of your fume hood. An enclosed reaction system would create pressure which would force the gases into your fume scrubbing system. Even at that it might not create enough pressure to push the gases up to your spray down tube. To create enough suction you would want to use a venturi system. 4Metals has a really good design of one on this forum.

A condenser between your reaction vessel and the exit point from your fume scrubber will condense much of the gases back into solution that will then make it's way back into your reaction vessel. This cuts down on the amount of gas that needs to be processed by your fume scrubbing.

I would make the spray down tube drop directly into the water reservoir.

The gases will only interact with the very surface of the water, so I would pack the spray down stack with some sort of media that water droplets can cling to, thus creating more wet surface to collect gasses.

Your reservoir should have an access port large enough to exchange solution and clean it.

The reservoir would also benefit by the installation of an ORP meter so that you know when you need to change out the solution.

A chemical resistant pump, rated for alkali and acidic solutions, in your reservoir, will allow you to easily exchange solutions

Depending on your intentions, you might want to collect the solution as it would be weak nitric acid. In my own design I recover as much of the dilute nitric acid as possible and use it for leaching.

You need a way to monitor the activated carbon, after it becomes saturated and no longer can absorb pollutants, the pollutants will simply just pass right through it. A PH meter between the first and second activated carbon chambers, and after the second, will tell you when the first becomes saturated and needs replacement. In that particular design the secondary activated carbon chamber acts as a safety. If you find that they both are working at the same rate you will then know you should add more activated carbon chambers. A PH meter will also tell you if you are exhausting any NOx. You can even use PH strips on the exhaust to see if they change color and know if you are exhausting NOx.

That's just off the top of my head. There is several posts on fume scrubbers. You might want to look up 4Metals posts on the subject as he has talked about it extensively and has provided plans as well.

Scott

EDITED:

Here is the thread on 4Metals design:

http://www.goldrefiningforum.com/phpBB3/viewtopic.php?f=40&t=9115&hilit=4metals+wet+fume+scrubbing

sorry i forget to add some info, the red box is blower, is it help?

oh, what i get from ur advice:

1) better put some thing at the NaOH spray to stuck the NaOH at that thing? sorry for bad english

NobleMetalWorks

Well-known member

Wookie said:sorry i forget to add some info, the red box is blower, is it help?

oh, what i get from ur advice:

1) better put some thing at the NaOH spray to stuck the NaOH at that thing? sorry for bad english

if you put material in your spray down stack that water droplets can cling to, you will collect far more of the gas as it passes through it. Those same water droplets will eventually make their way to your reservoir. It's an inexpensive addition but will drastically improve the efficiency of your fume scrubbing.

It would be even better if your spray down stack was on the other side of your reservoir, before the exhaust passes through your activated carbon.

It would also be better if you could push or draw your exhaust from the fume hood into the reservoir under the water line so that it's forced to come into contact with your solution in your reservoir.

Look at 4Metals design...

Scott

NobleMetalWorks said:Wookie said:sorry i forget to add some info, the red box is blower, is it help?

oh, what i get from ur advice:

1) better put some thing at the NaOH spray to stuck the NaOH at that thing? sorry for bad english

if you put material in your spray down stack that water droplets can cling to, you will collect far more of the gas as it passes through it. Those same water droplets will eventually make their way to your reservoir. It's an inexpensive addition but will drastically improve the efficiency of your fume scrubbing.

It would be even better if your spray down stack was on the other side of your reservoir, before the exhaust passes through your activated carbon.

It would also be better if you could push or draw your exhaust from the fume hood into the reservoir under the water line so that it's forced to come into contact with your solution in your reservoir.

Look at 4Metals design...

Scott

okay, thanks for ur advice, it's very useful, i already see 4metals design, but i think i just gonna use some stone at water droplets, cause i don't know what eductor name in my country. besides, it's just for a small amount of recovery. thanks anyway

rickbb

Well-known member

I've seen designs that use large glass balls, (like large marbles), in the condensing stack to increase surface area.

You can pick them up at home decorator type stores, designers use them in vases and around potted plants, etc.

You can pick them up at home decorator type stores, designers use them in vases and around potted plants, etc.

NobleMetalWorks

Well-known member

You can use all kinds of materials for rashing. I am using bio balls that were originally intended for salt water aquariums to grow bacteria on.

Here are some pictures of more conventional rashing materials

I have seen systems that use wiffle balls, PCV pipe that has been cut and holes drilled into it, anything really that provides a lot of surface area and will retain water droplets of sufficient size so that there is enough surface area to come into contact with the NOx gases being scrubbed.

Scott

Here are some pictures of more conventional rashing materials

I have seen systems that use wiffle balls, PCV pipe that has been cut and holes drilled into it, anything really that provides a lot of surface area and will retain water droplets of sufficient size so that there is enough surface area to come into contact with the NOx gases being scrubbed.

Scott

NobleMetalWorks said:You can use all kinds of materials for rashing. I am using bio balls that were originally intended for salt water aquariums to grow bacteria on.

Here are some pictures of more conventional rashing materials

I have seen systems that use wiffle balls, PCV pipe that has been cut and holes drilled into it, anything really that provides a lot of surface area and will retain water droplets of sufficient size so that there is enough surface area to come into contact with the NOx gases being scrubbed.

Scott

can i use shard?

NobleMetalWorks

Well-known member

When you say shard, do you mean stone chips?

You can use anything that doesn't react with the acids in a negative way, and even better if it helps to neutralize the acidic solution in your reservoir.

Scott

You can use anything that doesn't react with the acids in a negative way, and even better if it helps to neutralize the acidic solution in your reservoir.

Scott

no shard like broken glass. but i'll think i go for eco ball it's very cheap, i just have 1 question, can i use common aquarium pump? or i must use anti chemical?NobleMetalWorks said:When you say shard, do you mean stone chips?

You can use anything that doesn't react with the acids in a negative way, and even better if it helps to neutralize the acidic solution in your reservoir.

Scott

NobleMetalWorks

Well-known member

Aquarium pumps that pump water, usually work on magnetic drive. An impeller usually is comprised of a stainless steel shaft with a bladed propeller on one end, and a magnet surrounding the stainless steel shaft. The rest of the pump is encased in polypropylene plastic which is resistant to Nitric Acid. The only exposed part that might be attacked by weak or concentrated nitric acid would be the magnet itself, which I imagine can be easily replaced. As well, even though the stainless steel resists weak and concentrated nitric acid, you can purchase a ceramic shaft to replace it with.

Or you can just purchase a magnetic drive pump already intended for the purpose of what you are proposing, like this one:

http://www.marchpump.com/te-7r-md/

Scott

Or you can just purchase a magnetic drive pump already intended for the purpose of what you are proposing, like this one:

http://www.marchpump.com/te-7r-md/

Scott

Wookie -In your diagram you are showing a 3/4 inch pipe to draw the fumes out of your fume hood to your scruber

There is no way that is large enough to get the draw you need to remove the fumes from your hood - or as Scott said -"You are not going to provide enough suction to create positive air flow at the face of the fume hood."

You are going to need at least a 4 inch pipe & 5 or 6 inch would be better - you need to move the volume of air you have at the face of your hood through your exit pipe & 3/4 pipe is not going to move "volume"

Also your scruber stack needs to be even larger - at least 12 inch (or more)(in fact I would use at least a 35 gallon plastic drum & even better a 55 gallon drum as my scruber column on a hood this size) to slow down air speed which prolongs the time it takes the fumes to pass through the scruber collum which gives the fumes "time" to contact the scruber media (bio balls scott posted pick of) & react with the NaOH

If you don't slow down the air speed in your scruber column you won't get complete scrubing as the fumes are moving to fast through the column to affect reaction time

Lets go with 5 inch pipe out of hood to scruber then 35 or 55 gallon drum as scruber column then back to 5 inch pipe from scruber to carbon chamber - carbon chamber should also be larger to again slow down air speed (14 or 16 inch pipe then 5 inch pipe between the 2 carbon chambers & then back to 5 inch pipe as final out stack

Kurt

There is no way that is large enough to get the draw you need to remove the fumes from your hood - or as Scott said -"You are not going to provide enough suction to create positive air flow at the face of the fume hood."

You are going to need at least a 4 inch pipe & 5 or 6 inch would be better - you need to move the volume of air you have at the face of your hood through your exit pipe & 3/4 pipe is not going to move "volume"

Also your scruber stack needs to be even larger - at least 12 inch (or more)(in fact I would use at least a 35 gallon plastic drum & even better a 55 gallon drum as my scruber column on a hood this size) to slow down air speed which prolongs the time it takes the fumes to pass through the scruber collum which gives the fumes "time" to contact the scruber media (bio balls scott posted pick of) & react with the NaOH

If you don't slow down the air speed in your scruber column you won't get complete scrubing as the fumes are moving to fast through the column to affect reaction time

Lets go with 5 inch pipe out of hood to scruber then 35 or 55 gallon drum as scruber column then back to 5 inch pipe from scruber to carbon chamber - carbon chamber should also be larger to again slow down air speed (14 or 16 inch pipe then 5 inch pipe between the 2 carbon chambers & then back to 5 inch pipe as final out stack

Kurt

kurt said:Wookie -In your diagram you are showing a 3/4 inch pipe to draw the fumes out of your fume hood to your scruber

There is no way that is large enough to get the draw you need to remove the fumes from your hood - or as Scott said -"You are not going to provide enough suction to create positive air flow at the face of the fume hood."

You are going to need at least a 4 inch pipe & 5 or 6 inch would be better - you need to move the volume of air you have at the face of your hood through your exit pipe & 3/4 pipe is not going to move "volume"

Also your scruber stack needs to be even larger - at least 12 inch (or more)(in fact I would use at least a 35 gallon plastic drum & even better a 55 gallon drum as my scruber column on a hood this size) to slow down air speed which prolongs the time it takes the fumes to pass through the scruber collum which gives the fumes "time" to contact the scruber media (bio balls scott posted pick of) & react with the NaOH

If you don't slow down the air speed in your scruber column you won't get complete scrubing as the fumes are moving to fast through the column to affect reaction time

Lets go with 5 inch pipe out of hood to scruber then 35 or 55 gallon drum as scruber column then back to 5 inch pipe from scruber to carbon chamber - carbon chamber should also be larger to again slow down air speed (14 or 16 inch pipe then 5 inch pipe between the 2 carbon chambers & then back to 5 inch pipe as final out stack

Kurt

but my fume hood is small, did i still use 5" for main pipe? if i use big pipe, i'm afraid my blower not have enough power to suck the air, it's okay to use 2" for main pipe and 5" for scrubber collumn?

Wookie said:but my fume hood is small, did i still use 5" for main pipe? if i use big pipe, i'm afraid my blower not have enough power to suck the air, it's okay to use 2" for main pipe and 5" for scrubber collumn?

No 2" is not enough for a 50"X 40" face - especially if you are planing to use the fume hood as your primary fume evacuation/scrubing system durring reaction when high volumes of fumes are produced - without doing the calculations (which I don't have time for) I would say you are going to want at least 4" (you might get away with 3")

this is not really what fume hoods are designed for (meaning as primary evacuation/scrubing systems) they are really designed as secondary evacuation systems to evacuate low level fumes produced while setting up closed system reactors with vacuum assist scrubers &/or the low level fume produced while handling chems &/or solutions before &/or after actual reaction

I am not saying a fume hood with scruber can't be used as your primary system - just that its not really what they are designed for

You really need to consider setting up a closed vacuum assisted reactor/scruber system & use your hood for setting up the reactor/scruber & handling chems & solution before & after reaction

If you are going to use your hood as a primary evacuation/scrubbing system you have to concider both air speed & air volume (durring reaction you need to move a LOT of volume)

Volume starts at the hood face & speed starts at the exit pipe (due to restriction) so the pipe needs to be small enough to get air speed going in order to get the volume at the face moving - but the pipe also needs to be large enough to handle the volume moving from the face --- if the pipe is to small you will have plenty of air speed but it wont handle the volume & the volume the pipe cann't handle will go the only other place it can go - which is out the face of the hood & in your face

As far as your scruber chamber (&/or carbon chambers) don't worry to much about them being to big - in fact the more fumes you are trying to scrub the bigger you want them --- the purpose of the larger scrubing chambers is to slow air speed down so the fumes have time to react with the NaOH & the carbon in those chambers --- as long as the final exit pipe is the same size as the pipe at your hood it wont affect the volume or speed that the air/fumes move through the system --- the air fumes simply slow down in those chamber to allow for reaction time

Also - your hood needs to have baffles at the back & top so that it draws the fumes to the back bottom & back mid point of the hood (primarally) & as well at the top front of the hood to catch any fumes trying to go out the top front not caught going out the back bottom & back mid point

And yes your blower needs to match the system

hope this helped

Kurt

rickbb

Well-known member

I read a post or somewhere that a good fume hood has 150 cfm of air flow for every square foot of hood face, (opening).

Your 50 x 40 inch face is 2000 sq in, or 13.89 sq feet. According to this, you would need a fan/ducting setup that would draw at least 2,083 cfm. thats a lot.

You also have to keep in mind that all the bends, the length of the ducting and all the rashing objects cut down on that flow. Making you need an even bigger exhaust fan.

I cut down on the face of my hood by making a hinged plexaglass front. It leaves about 6 inches open across the bottom so I can reach in to work, but reduces the face area so I get better air flow/fume exhausting. When I'm not generating fumes I can open it up for full access.

Your 50 x 40 inch face is 2000 sq in, or 13.89 sq feet. According to this, you would need a fan/ducting setup that would draw at least 2,083 cfm. thats a lot.

You also have to keep in mind that all the bends, the length of the ducting and all the rashing objects cut down on that flow. Making you need an even bigger exhaust fan.

I cut down on the face of my hood by making a hinged plexaglass front. It leaves about 6 inches open across the bottom so I can reach in to work, but reduces the face area so I get better air flow/fume exhausting. When I'm not generating fumes I can open it up for full access.

rickbb said:I read a post or somewhere that a good fume hood has 150 cfm of air flow for every square foot of hood face, (opening).

Your 50 x 40 inch face is 2000 sq in, or 13.89 sq feet. According to this, you would need a fan/ducting setup that would draw at least 2,083 cfm. thats a lot.

You also have to keep in mind that all the bends, the length of the ducting and all the rashing objects cut down on that flow. Making you need an even bigger exhaust fan.

I cut down on the face of my hood by making a hinged plexaglass front. It leaves about 6 inches open across the bottom so I can reach in to work, but reduces the face area so I get better air flow/fume exhausting. When I'm not generating fumes I can open it up for full access.

That sounds about right & this is also why fume hoods are not ment to be used for your primary fume control (actual reaction fume control) but rather for low level fume work (handling chems & solution before & after reaction)

I am running 2 fume hoods with 60"X42" (not that much biger then 50X40) they each have 12" pipe (duct) & they have a hard time handling full fume reactions (2 liter & larger reaction vessels) even with face closed down to 6"

Which is why its better to set up reaction systems with vacuum assisted scrubers & use the hood for what it is really intended for

Kurt