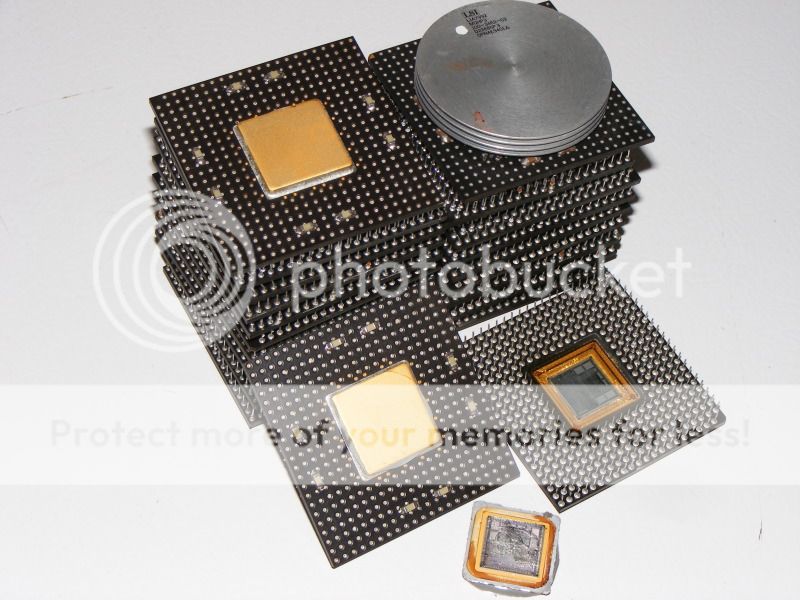

I still think you should cut the center parts out if you can.

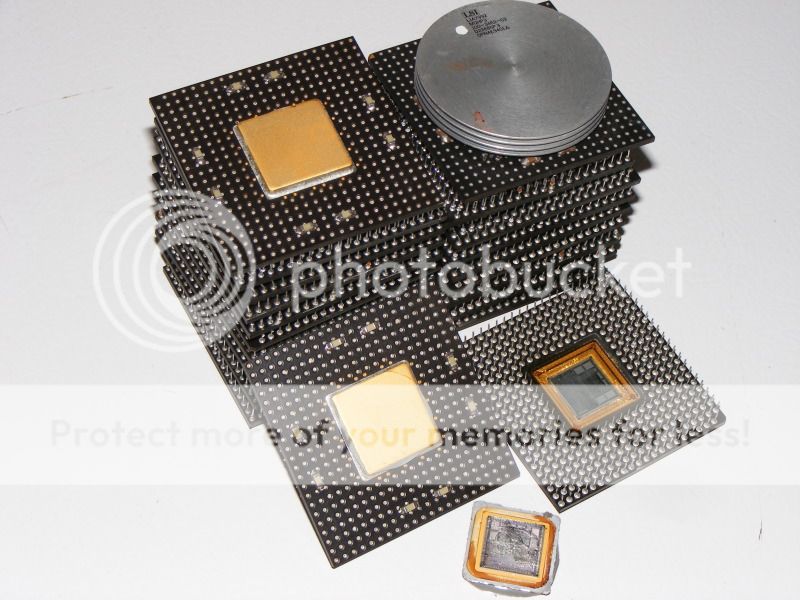

You have two different sorts of scrap here, gold plated + bond wires and flash plated gold dissolved in tin with a few percent silver. To mix it in a rather small batch is just to make things complicated.

To try to get to the silver and gold with the pins I would treat it in HCl, it will dissolve the tin and kovar, the silver will be converted to silver chloride (I think) and the gold that is mixed up in the tin will drop as a very fine sediment or being locked in with the silver chloride.

Then I would decant the dissolved kovar / tin mixture and also removing the left over circuit boards, it will still contain copper buried in the PCB and would affect the process later. You have to check that all holes are free of any sediment or left over metals from the pins.

Now you will have a sludge of silver chloride and microscopic gold particles and probably a lot of other metal oxides. Next step is to turn the silver chloride into metal and digest it with nitric, decant / filter and cement on copper. If some gold goes into solution it will follow the silver and cement with it. Any remaining material could be treated in AR to get gold out of it.

... but that is how I would do it if I had to, I'm not totally convinced it is economically to do it on such a small batch. The silver is just a few percent of the tin and gold is only flash plated, it is only there to protect the surface before the pins are soldered, not a mechanical protection for wear as in a contact surface. It will be a lot of work for very little return.

Disclaimer : I have never processed these type of chips so my procedure is purely theoretical and could contain fatal errors and could be improved in many ways. Read and use at your own risk, think it through for your self. :mrgreen:

Göran