-

Please join our new sister site dedicated to discussion of gold, silver, platinum, copper and palladium bar, coin, jewelry collecting/investing/storing/selling/buying. It would be greatly appreciated if you joined and help add a few new topics for new people to engage in.

Bullion.Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stainless Steel Silver Cell _smallsilvercell_

- Thread starter kadriver

- Start date

Help Support Gold Refining Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

goldsilverpro said:Excellent videos, Ralph. So far, the best videos produced by anyone that I can think of. And, they're free!

Can I echo that sentiment.

With just a little knowledge and effort those videos show exactly how to refine your own silver and as I have said before that cell is awesome in its simplicity of use and construction. I made a similar set up but using a 15 litre container with a large pastic colander as the filter and feed stock holder after seeing Palladiums cell and it is so simple to use.

The fun part is trying to recover and refine the slimes!

shaftsinkerawc

Well-known member

Thank You for the Video's. Good Health to You & Yours.

Irons

Well-known member

Great Vids, Ralph. These should be on everyone's bucket list. 8)

rewalston

Well-known member

Very nice Ralph, makes me wish I had some  All I have silver wise is a sterling ring and a couple lbs of keyboard mylar. I'm going to try melting the mylar down as Steve suggested but I need to find something to melt it in, I don't want to use either of the small melting dishes I have, those I'm saving for gold and refined silver.

All I have silver wise is a sterling ring and a couple lbs of keyboard mylar. I'm going to try melting the mylar down as Steve suggested but I need to find something to melt it in, I don't want to use either of the small melting dishes I have, those I'm saving for gold and refined silver.

Rusty

Rusty

$85.22

$171.00

Catalysis in the Refining of Fischer-Tropsch Syncrude (Catalysis Series, Volume 4)

Basi6 International

$80.54

$120.00

Petroleum Refining: Technology, Economics, and Markets, Sixth Edition

Rockwood_Books

$19.99

$24.99

PAXCOO Jewelry Making Supplies Kit with Jewelry Tools, Jewelry Wires and Jewelry Findings for Jewelry Repair and Beading

Paxcoo Direct

$8.99

5 Pack Jewelry Pliers Tool Set, Includes Round, Chain, Needle, Bent & Zipper Pliers for Repair, Wire Wrapping & Crafts

ZHUHAI DIANDIAN Technology Co., Ltd

rewalston

Well-known member

two thumbs up, good videos

edsikes

Well-known member

wow palladium.. i feel like i just crammed for a final i wasnt planning on taking but watching those videos just answered every question i had about silver cell operation..... im gonna try my hand at it in the spring.... one question though... is this safe to do indoors or does it still need to be under a fume hood even after the electrolyte has been diluted? just curious because i would like to clear my garage out some so i dont have to leave this outside.

No acids can really be used inside as they will cause damage to the fabric of the building so some extraction is a must also the fumes will do your own health no good and any metals around will corrode.

edsikes

Well-known member

oh ok... thought that maybe since the nitric was so dilute that it may not be a problem but i wasnt sure so i wanted to ask first! thanks!

ExNuke

Member

kadriver said:Dawg,

I would suggest that you have the engineer install several (4 equidistant) lugs around the periphery of the tank.

Then, using equal length leads, you can attach the negative from your power supply to these four points

If you have just one lug, then the electrical flow will cause the silver to form more densely at that one point in the cell.

By having four lugs and using equal length leads to each lug, you will distribute the electrical flow evenly and the silver crystal formation will be more uniform.

Now I see what you were talking about in your PM.

Thank you,

kadriver

This thread has some age on it so it's too late to offer anything to those who were in it but a suggestion for anyone new reading it might be well recieved.

For making a good connection to their stainless bowl, find or buy a piece of sheet copper from a craft store and make a permanent connection to it for your negative lead. Then just set your bowl on it. The weight of the full bowl will make a good low resistance connection. It takes the minimal actual contact area of an alligator clip out of the circuit. I found that putting an up side down 4" watch glass in the bottom of the bowl reduces the risk of fingers of crystals reaching the basket and the slight loss of urface area isn't really noticeable.

Sputins

Member

- Joined

- Oct 28, 2014

- Messages

- 20

ExNuke said:kadriver said:Dawg,

I would suggest that you have the engineer install several (4 equidistant) lugs around the periphery of the tank.

Then, using equal length leads, you can attach the negative from your power supply to these four points

If you have just one lug, then the electrical flow will cause the silver to form more densely at that one point in the cell.

By having four lugs and using equal length leads to each lug, you will distribute the electrical flow evenly and the silver crystal formation will be more uniform.

Now I see what you were talking about in your PM.

Thank you,

kadriver

This thread has some age on it so it's too late to offer anything to those who were in it but a suggestion for anyone new reading it might be well recieved.

For making a good connection to their stainless bowl, find or buy a piece of sheet copper from a craft store and make a permanent connection to it for your negative lead. Then just set your bowl on it. The weight of the full bowl will make a good low resistance connection. It takes the minimal actual contact area of an alligator clip out of the circuit. I found that putting an up side down 4" watch glass in the bottom of the bowl reduces the risk of fingers of crystals reaching the basket and the slight loss of surface area isn't really noticeable.

This thread does have some age to it, but it remains one of the most relevant to silver refiners. The idea of the conductive plate to sit your bowl on seems like a pretty good idea. In theory it should ensure the equal distribution of conduction current from the applied EMF.

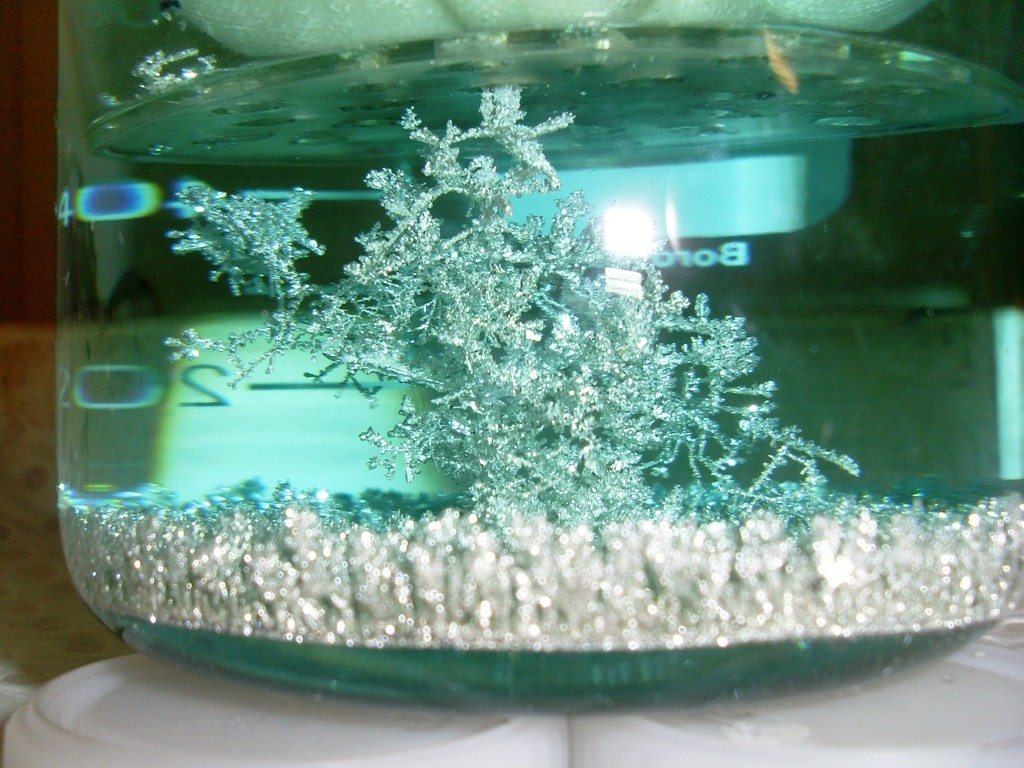

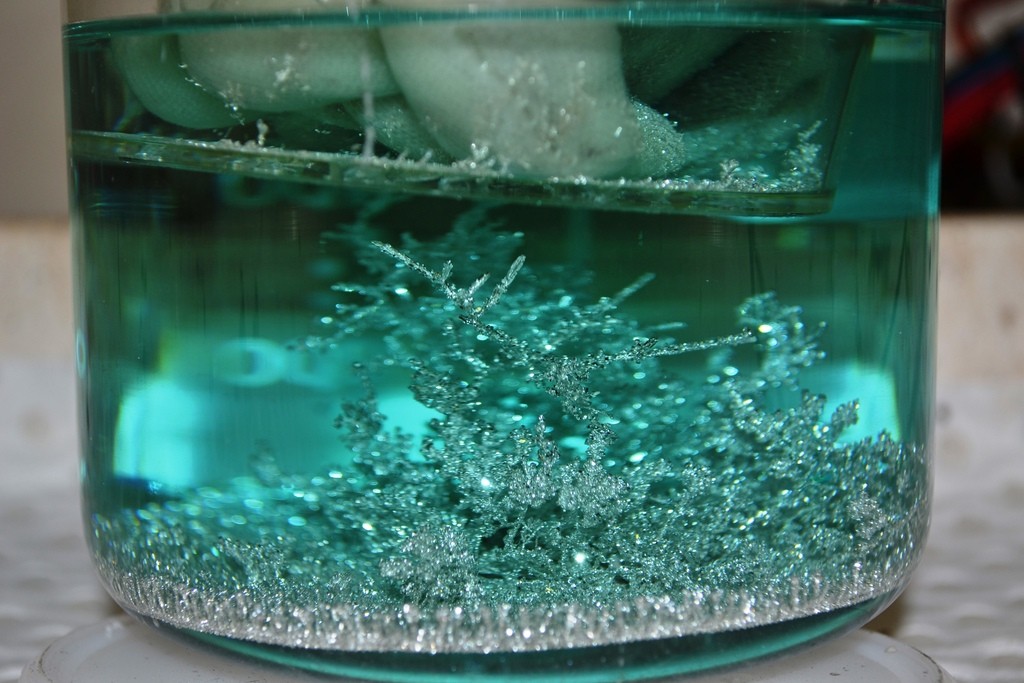

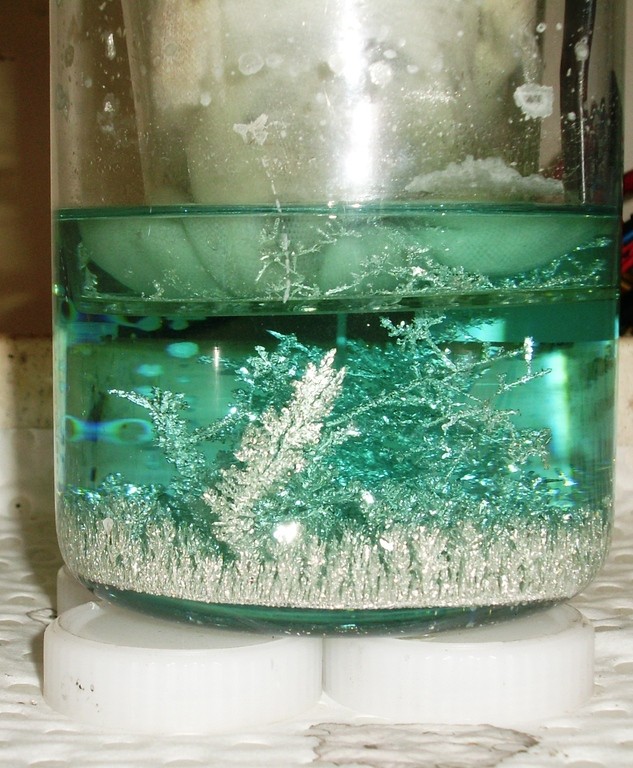

Given that the aim of the electrolytic silver cell is to produce five nines fine silver, in the form of silver crystals. I’ve tried to focus on not just the refinement as such, but the formation and process of the formation of the silver crystals themselves. I’ve produced about 2kg of crystals thus far.

I’ll soon post some photos of some of the larger crystals I’ve been able to produce. I’m looking into producing some quality photos of certain crystals. Also I know someone, who knows someone who has access to a million dollar Scanning Electron Microscope (SEM). I’ve received several pictures of the scanned crystals from 1mm scale down to 5um.

I’ll post these shortly… Stay tuned.

(Harold, is it acceptable to begin a new thread focused on the Silver Crystals themselves, on their size, shape & formation etc. as opposed to the simply the silver cell and the production)?