You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Step Refining?

- Thread starter gogold

- Start date

Help Support Gold Refining Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Noxx

Well-known member

I don't know how to refine those but I suggest to refine CPUs and pins apart.

AuMINIMayhem

Well-known member

Gogold.. you might want to read my post here http://goldrefiningforum.com/phpBB3/viewtopic.php?t=381 before you get started.. there's some helpful links as well.. CCA's and PCB's can be a real b---h to recover if they've been "conformal coated".. CC (for short) is used to protect the board and all the components from a wide range of elements, depending on what the final product was.. could be heat, water, cold, acid, fire, radiation resistant.. depending on the coating you may have to change your methods to get at the printed circuits themselves (assuming they're even gold)..

Good luck, it looks promising, but I can't tell from the picture what kind, if any, protective coatings were used on the board..

Derek

Good luck, it looks promising, but I can't tell from the picture what kind, if any, protective coatings were used on the board..

Derek

AuMINIMayhem

Well-known member

you know what?.. I was thinking (uh-ohhhhh) I would start by workin on the components.. desolder all the little bits and check out lazersteve's post on the Hydrochloric acid method, then worry about the board later once you can get a better look at it..

gogold,

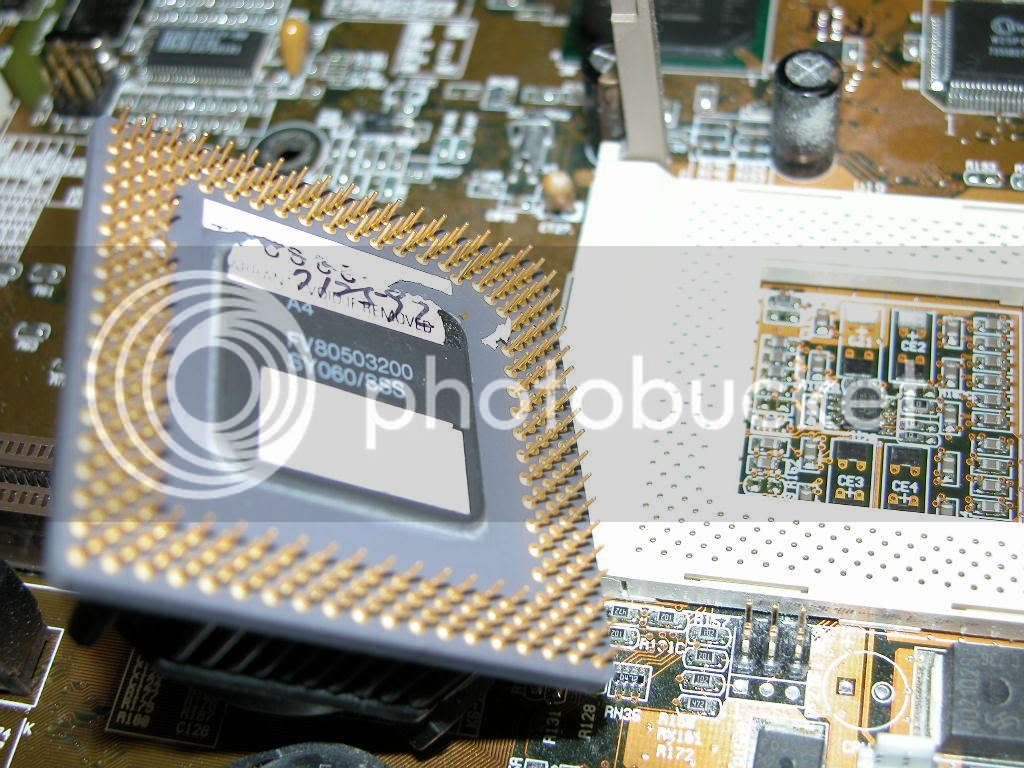

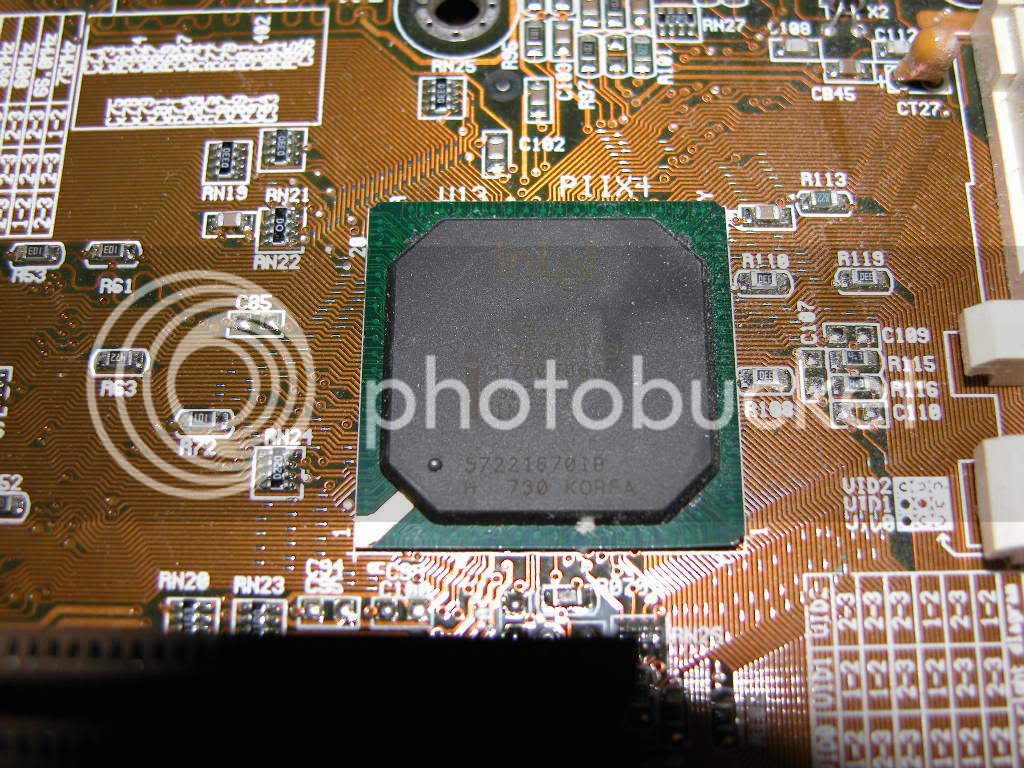

In my opinion it's comes down to how valuable is my time. By this I mean this: If it takes me days on end to harvest the gold from a source, and the yield of gold is minimal compared to my efforts, then I have wasted time that is better spent elsewhere. There are parts of the board pictured that are obviously worth the effort of recovering (CPU, Memory sticks, cards, and pin headers).

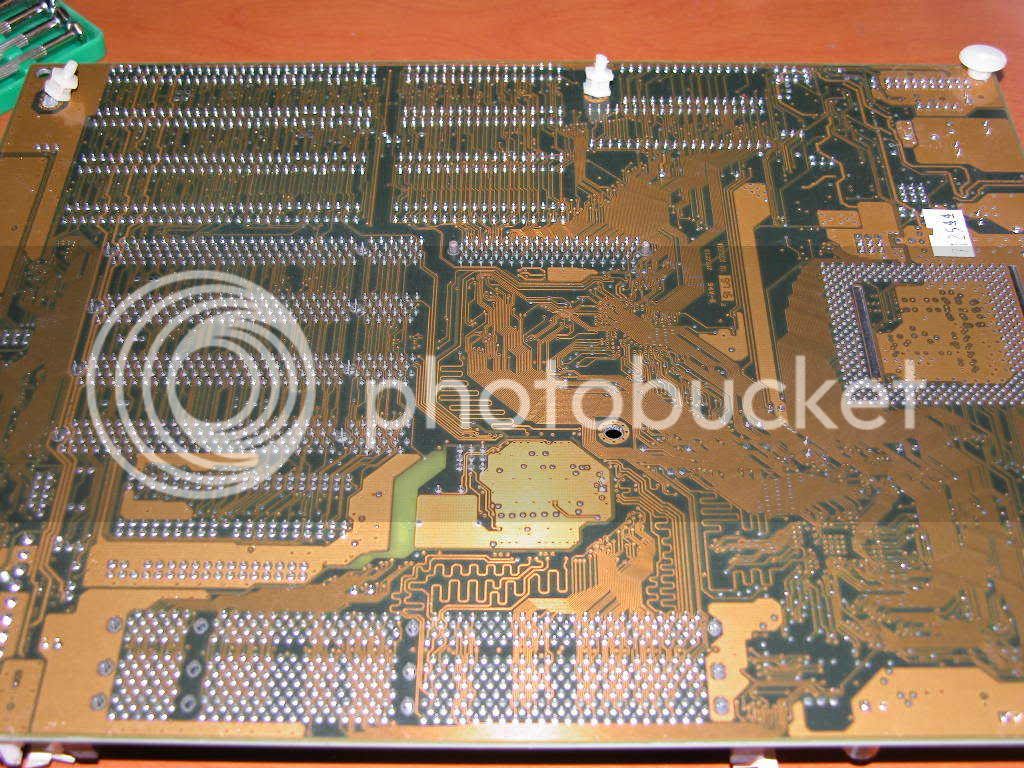

The traces on the board pictured are all copper. The coating Mayhem mentioned and the solder mask (the golden colored laminent you see on the bottom of the board) makes the board difficult and time consuming to process, for very little return (some copper and little, if any, gold).

The second thing to consider is the chemical cost. Do you want to use your precious nitric dissolving the mass quantities of tin, copper, and nickel which is the bulk of the metals on the board and slots? Or do you want to use this nitric for a controlled 'attack' on the higher yielding parts previously listed?

The point I'm trying to make is that if you plan your processing time properly you can do your harvesting work while your higher grade gold plated parts are soaking or dissolving. This is why I like the slower indirect (nondissolving- gold doesn't dissolve) methods of recovery. I can harvest my boards of the higher yield scrap, put this into the appropriate bath and them continue my harvesting efforts while the gold is being processed. This way I get the most for the least effort.

A few added bonuses to slower methods are:

1) Cheap readily available chemicals.

2) Low fumes

3) Little to no babysitting of the reaction.

4) Your gold always remains visible during the recovery process. This is a big plus for newbies who frequently are 'losing' their gold once it 'dissapears' into a liquid solution. If you can see the gold, you know right where it is at all times and it's much harder to 'lose'.

There are several other threads on the subject, search for 'PCB' or 'board' and you'll find them.

Steve

In my opinion it's comes down to how valuable is my time. By this I mean this: If it takes me days on end to harvest the gold from a source, and the yield of gold is minimal compared to my efforts, then I have wasted time that is better spent elsewhere. There are parts of the board pictured that are obviously worth the effort of recovering (CPU, Memory sticks, cards, and pin headers).

The traces on the board pictured are all copper. The coating Mayhem mentioned and the solder mask (the golden colored laminent you see on the bottom of the board) makes the board difficult and time consuming to process, for very little return (some copper and little, if any, gold).

The second thing to consider is the chemical cost. Do you want to use your precious nitric dissolving the mass quantities of tin, copper, and nickel which is the bulk of the metals on the board and slots? Or do you want to use this nitric for a controlled 'attack' on the higher yielding parts previously listed?

The point I'm trying to make is that if you plan your processing time properly you can do your harvesting work while your higher grade gold plated parts are soaking or dissolving. This is why I like the slower indirect (nondissolving- gold doesn't dissolve) methods of recovery. I can harvest my boards of the higher yield scrap, put this into the appropriate bath and them continue my harvesting efforts while the gold is being processed. This way I get the most for the least effort.

A few added bonuses to slower methods are:

1) Cheap readily available chemicals.

2) Low fumes

3) Little to no babysitting of the reaction.

4) Your gold always remains visible during the recovery process. This is a big plus for newbies who frequently are 'losing' their gold once it 'dissapears' into a liquid solution. If you can see the gold, you know right where it is at all times and it's much harder to 'lose'.

There are several other threads on the subject, search for 'PCB' or 'board' and you'll find them.

Steve

AuMINIMayhem

Well-known member

yup.. agreed.. I have a bunch of boards I plan on doing eventually and I'm just taking any gold plated components and probably chucking the boards (unless somebody wanted them) , but they're almost certainly hardly worth the time (and the mess of molten fiberglass, etc..)

gogold,

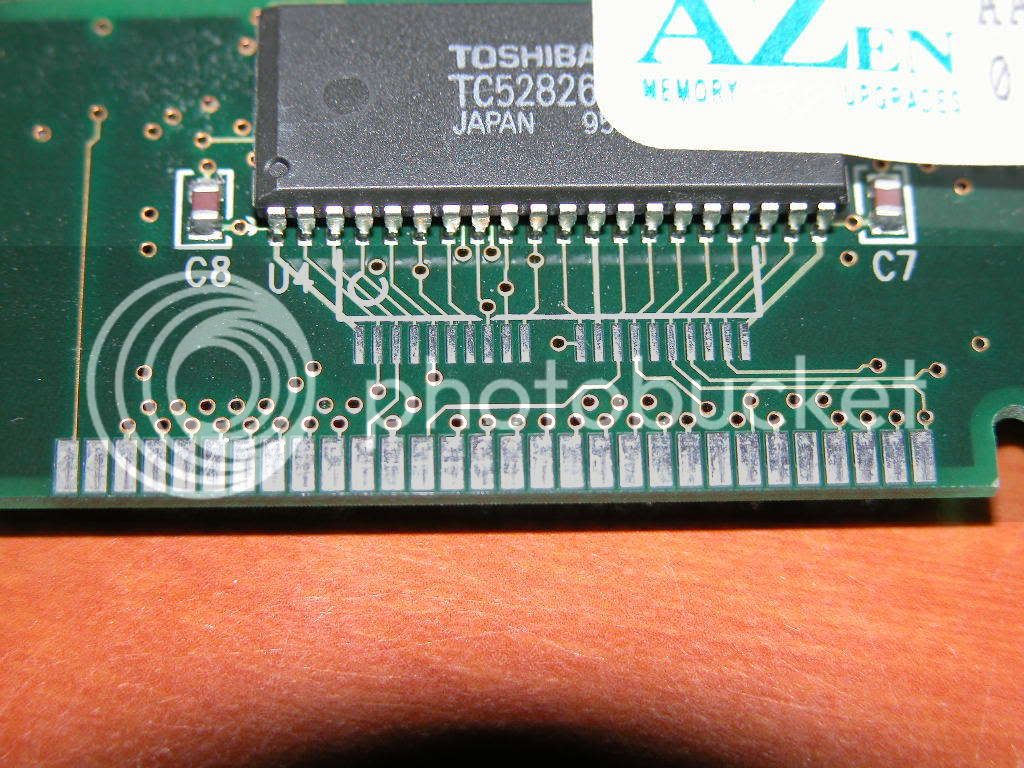

The typical 'silver' memory finger is merely tin/lead solder. There have been some claims that a few rare silver colored board fingers that are plated with palladium or other pgms. This may be possible in VERY old equipment of aerospace grade. The memory you have pictured is very the common 72 pin SIMM variety.

The hard drive platter have been discussed elsewhere on the forum. Try searching for Hard Drive.

Here's a good thread for starters:

Hard Drives

Steve

The typical 'silver' memory finger is merely tin/lead solder. There have been some claims that a few rare silver colored board fingers that are plated with palladium or other pgms. This may be possible in VERY old equipment of aerospace grade. The memory you have pictured is very the common 72 pin SIMM variety.

The hard drive platter have been discussed elsewhere on the forum. Try searching for Hard Drive.

Here's a good thread for starters:

Hard Drives

Steve

AgAuPtRh

Well-known member

the fingers on the memory you have in the photo's is more likely than not a tin-lead alloy. Not really worth much at all.

The discs on your hard drive have a Platinum cobalt coating. Worth keeping and processing once you have enough to make it worth your time. Also on your hard drives -- the cases are made of aluminum -- good to have around and can fetch a good price at the scrap yard when you have a good pile of it. Keep your aluminum scrap. And the copper. I save it all.

Welcome tot he recovery/refining hobby. Where every empty container finds a purpose -- no matter what size it is.

Steve K

The discs on your hard drive have a Platinum cobalt coating. Worth keeping and processing once you have enough to make it worth your time. Also on your hard drives -- the cases are made of aluminum -- good to have around and can fetch a good price at the scrap yard when you have a good pile of it. Keep your aluminum scrap. And the copper. I save it all.

Welcome tot he recovery/refining hobby. Where every empty container finds a purpose -- no matter what size it is.

Steve K

darkelf2x1

Well-known member

- Joined

- Apr 7, 2007

- Messages

- 48

should also save electronic components as they can fetch more than the precious metals in them - consult the local electronics recycler for stuff that can be resold