- Joined

- Feb 25, 2007

- Messages

- 8,361

The amount isn't critical. I used to cover the preciptated gold, then heat.Nickpearl said:How much household ammonia do I use to wash?

Thus far, after AR, I decant with water several times. Then I HCL

Rinse some more.

I would assume I drop in as much ammonia in one of these washes as I did with HCL (in my case, for the 2.6g button, I used maybe 2-3 ml).

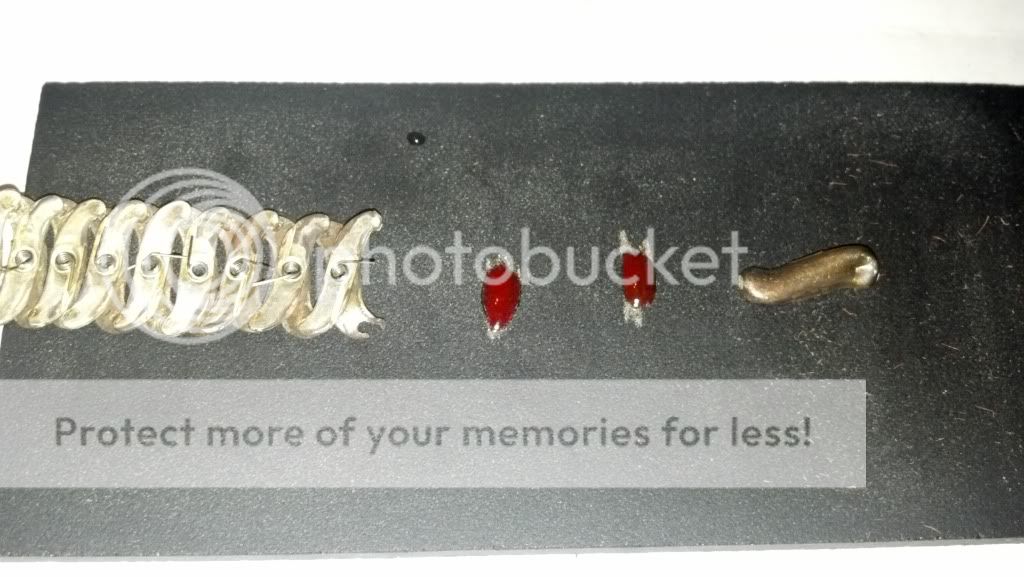

I avoided contact with the gold, but I also kept the vessel covered with a watch glass, and boiled each operation. If you mess with the gold much, you start scratching the beaker, which renders it virtually useless for future precipitation. The brisk boiling will flush the cemented gold of dissolved solids adequately, especially if you have double refined. If you have, there's precious little to be removed, anyway. It should have all be left behind in the barren solution.After the ammonia wash, I would expect to rinse repeatedly (under heating pad heat), stirring. By then, of course, the gold is starting to clump.

~~ Do I then crush the clumps to make sure it's rinsed or just stir?~~

By the way, my ammonium hydroxide wash came in the middle of the two HCl wash/rinse cycles. Seemed to work for me, and I could often see the results of the ammonium wash.

Certainly does no harm---but I used only tap water for gold refining. I never found it to be a problem, and I achieved a level of quality that was more than acceptable. I do NOT claim to have achieved 4n's, however, but I exceeded 9995 routinely. You can tell if your gold is pure--it forms no oxide skin when melted, and cools bright. Appearance is NOT improved by pickling.Lastly, should my last two rinses be with distilled water?

Cold, here, isn't an issue, but we sure as hell get our share of rain (cool and damp). That's the way it is in the pacific north wet. :lol:

Harold