Hello everyone!

I started 2 batches of pins few days ago, one batch of 90g fully plated non-magnetic pins and another 400g partially plated pins, those are mixed, mostly non-magnetic and some semi-magnetic ones. All are solder free.

Added 200ml 32% HCl and ~7.5ml 20% H2O2 to the fully plated.

1200ml 32% HCl and ~30ml 20% H2O2 to the partially plated mixed pins.

Solution became pale yellow in both cases instead of pale green. Checked again about 4-6 hours later and solution was colorless.

Both stayed like that til next day, so I added little bit of H2O2 to both and they gave some very pale green and back to yellow about an hour or 2 later.

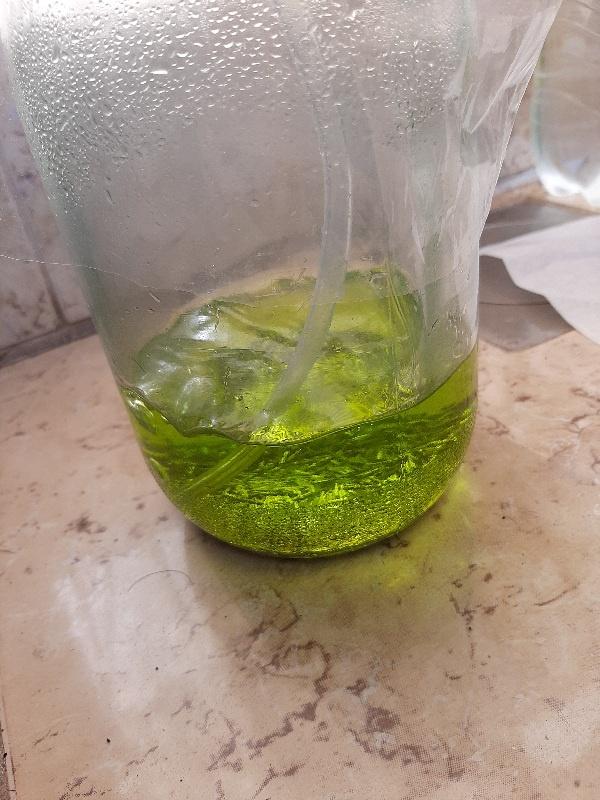

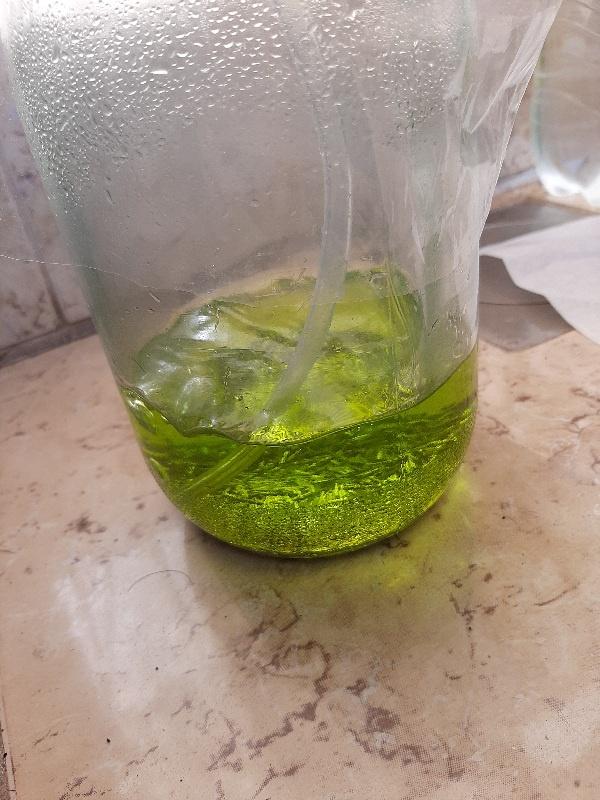

Couple of more days (about 5 days since the begining) I added 50ml of H2O2 to both and they both turned to a light green color. But again 1-2 hours later it started fading though it kept pale greenish for longer..

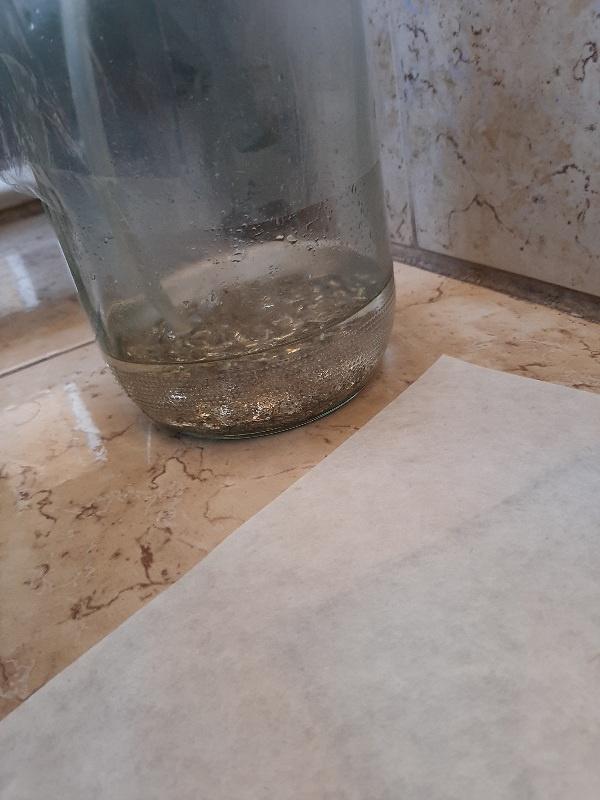

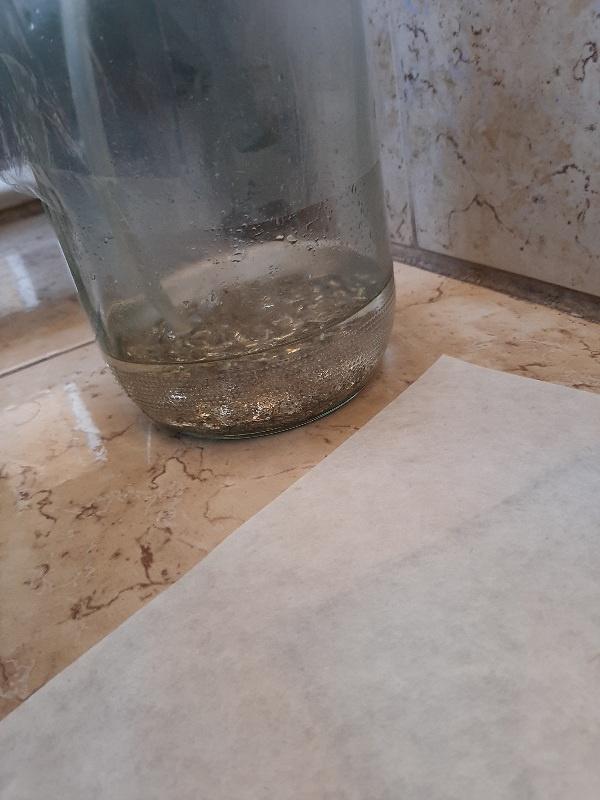

Now (few more days later) they are very pale yellow with barely any green tint, then completely colorless after I took those pics

Adding more H2O2 seems futile considering that I'm air bubbling too (unless maybe if I add 1 liter?) Or maybe pour off the solution and let the pins sit in the air for a day?

I'm assuming that or something is cementing out the copper? But colorless like that? Fully plated pins in the jar are non-magnetic and as I mentioned all solder free so basically all/mostly copper I assume.. Both jar and bucket are showing almost exact same behavior. It has been about 8-9 days total now and the reaction is as you see, going backwards .

.

Should I just wait it out or something need to be done?

Any Idea or help would be appreciated.

I started 2 batches of pins few days ago, one batch of 90g fully plated non-magnetic pins and another 400g partially plated pins, those are mixed, mostly non-magnetic and some semi-magnetic ones. All are solder free.

Added 200ml 32% HCl and ~7.5ml 20% H2O2 to the fully plated.

1200ml 32% HCl and ~30ml 20% H2O2 to the partially plated mixed pins.

Solution became pale yellow in both cases instead of pale green. Checked again about 4-6 hours later and solution was colorless.

Both stayed like that til next day, so I added little bit of H2O2 to both and they gave some very pale green and back to yellow about an hour or 2 later.

Couple of more days (about 5 days since the begining) I added 50ml of H2O2 to both and they both turned to a light green color. But again 1-2 hours later it started fading though it kept pale greenish for longer..

Now (few more days later) they are very pale yellow with barely any green tint, then completely colorless after I took those pics

Adding more H2O2 seems futile considering that I'm air bubbling too (unless maybe if I add 1 liter?) Or maybe pour off the solution and let the pins sit in the air for a day?

I'm assuming that or something is cementing out the copper? But colorless like that? Fully plated pins in the jar are non-magnetic and as I mentioned all solder free so basically all/mostly copper I assume.. Both jar and bucket are showing almost exact same behavior. It has been about 8-9 days total now and the reaction is as you see, going backwards

Should I just wait it out or something need to be done?

Any Idea or help would be appreciated.