Hi guys,

After studying a lot I decided to start recovering platinum from an alloy. I tell you my story.

It had an initial alloy weight of 480g. This had the following proportions: 500 Au, 36 Pt, 250 Ag, 184 Cu, 6 Pd and a little Zn and Ni.

Since the amount of silver was high, I decided to add copper to lower the proportion to 10%. I added 739.2g of Cu and made shot from this.

I was left with a weight of 1227g of alloy with proportions:

Cu:684

Au: 189.63

Pt:17.25

Ag:91.58

and some Zn, Pd and Ni.

Now the silver ratio was low enough to be able to attack directly with AR and heat.

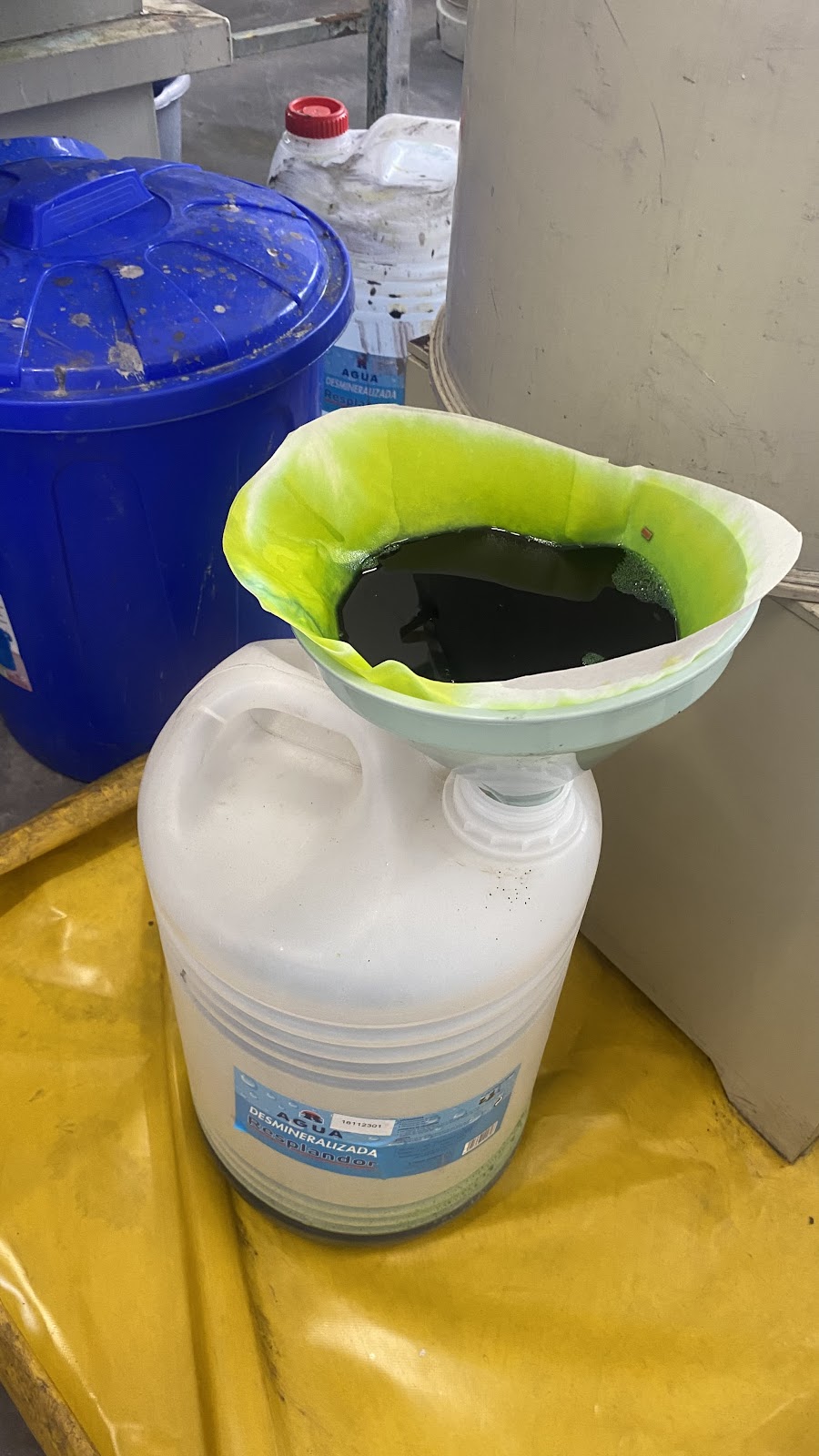

Since there was a lot of it, it took too long to react, I had to leave and the reaction was not over. So the next day I filtered it and added fresh aqua regia to continue reacting the grit that remained undissolved.

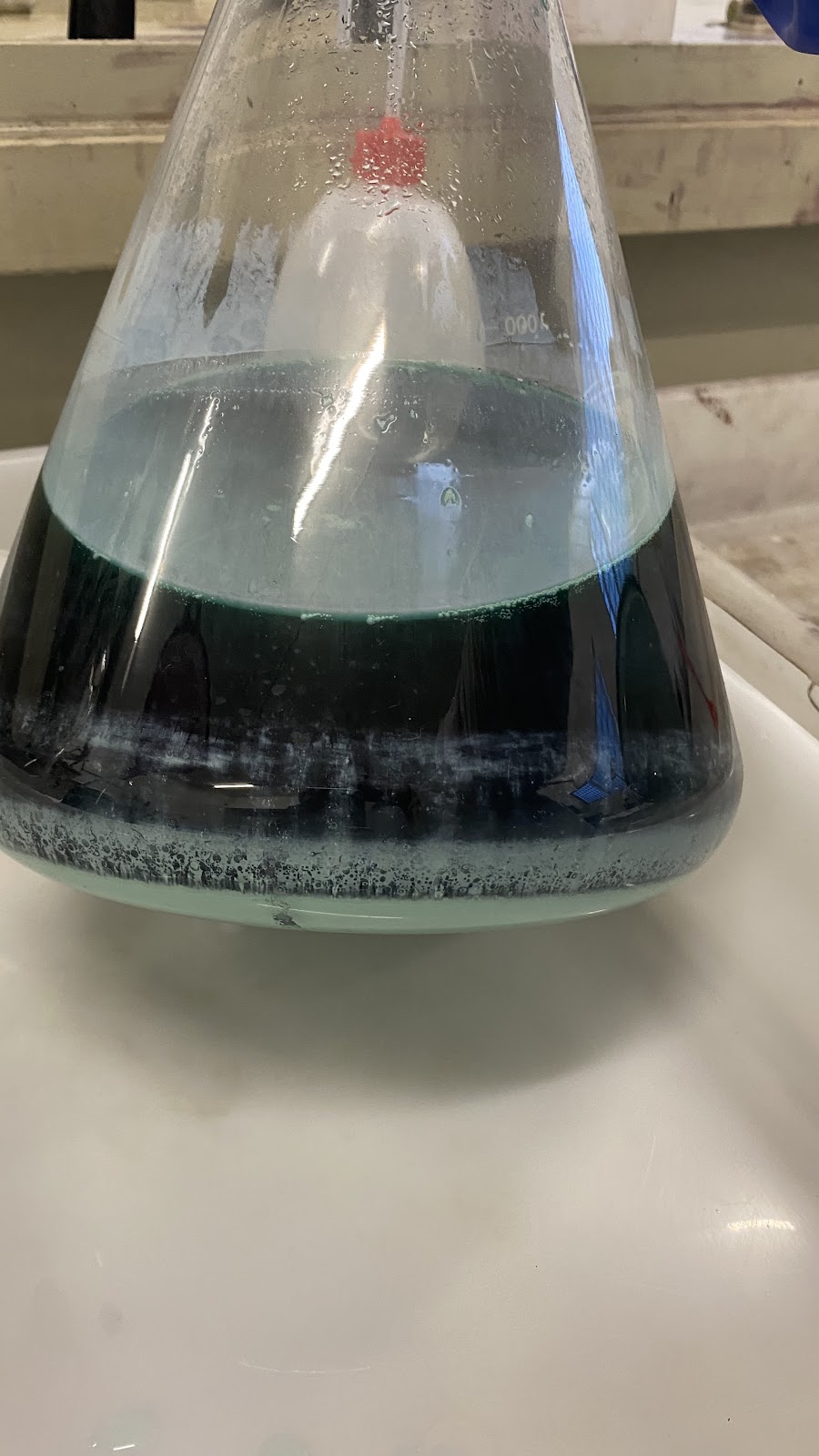

I watched as a green scab formed, the likes of which I had never seen before. I thought that since it had so much copper, it was possibly CuCl2, could anyone confirm? attached photo

I continued filtering the solution to remove any silver chlorides that might be present and leaving the solution clean.

After this point, I added 12.5g of ammonium chloride to my solution. and nothing happened.

Then I thought I had forgotten the step of removing the HNO3, I heated for several days to obtain the syrup, I also added sulfamic acid, and I still never managed to obtain the orange ammonium hexachloroplatinate powder.

I wanted to ask if you know if a large amount of copper can negatively affect the recovery of platinum, and if so, how could it act when the amount of silver is greater than 12%?

I hope you can help me, I don't know why sometimes platinum recoveries don't go well. I would like to understand what is happening.

Thank you very much and best regards.

After studying a lot I decided to start recovering platinum from an alloy. I tell you my story.

It had an initial alloy weight of 480g. This had the following proportions: 500 Au, 36 Pt, 250 Ag, 184 Cu, 6 Pd and a little Zn and Ni.

Since the amount of silver was high, I decided to add copper to lower the proportion to 10%. I added 739.2g of Cu and made shot from this.

I was left with a weight of 1227g of alloy with proportions:

Cu:684

Au: 189.63

Pt:17.25

Ag:91.58

and some Zn, Pd and Ni.

Now the silver ratio was low enough to be able to attack directly with AR and heat.

Since there was a lot of it, it took too long to react, I had to leave and the reaction was not over. So the next day I filtered it and added fresh aqua regia to continue reacting the grit that remained undissolved.

I watched as a green scab formed, the likes of which I had never seen before. I thought that since it had so much copper, it was possibly CuCl2, could anyone confirm? attached photo

I continued filtering the solution to remove any silver chlorides that might be present and leaving the solution clean.

After this point, I added 12.5g of ammonium chloride to my solution. and nothing happened.

Then I thought I had forgotten the step of removing the HNO3, I heated for several days to obtain the syrup, I also added sulfamic acid, and I still never managed to obtain the orange ammonium hexachloroplatinate powder.

I wanted to ask if you know if a large amount of copper can negatively affect the recovery of platinum, and if so, how could it act when the amount of silver is greater than 12%?

I hope you can help me, I don't know why sometimes platinum recoveries don't go well. I would like to understand what is happening.

Thank you very much and best regards.