pugle1

Member

Hi folks,

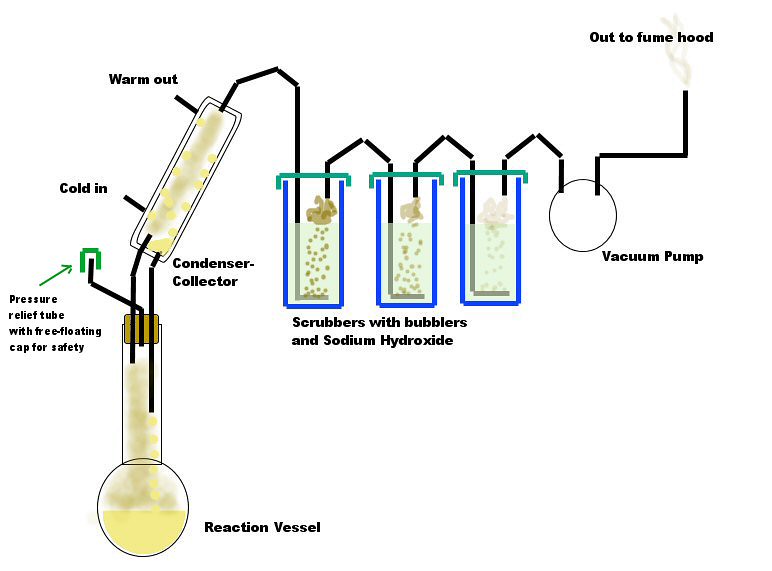

I understand the principles of why condensing is a good idea... to let the reagents work longer with less loss, but I'm not entirely sure on the best way to set a system up which would also include a fume / vapor scrubber. Before I actually start to build a fume hood and condenser / scrubber system, I'd like to know if anyone was willing to post a good schematic of their working system. Not of all the intricate details of the scrubber as such, but rather the incorporation of the condenser within the system.... ie reaction vessel / condenser / scrubber.

Somewhere along the way I'm getting confused as to how the vapors eventually leave the system after having gone through the condenser. Can anyone fill me in, or give a little advice please? And also, any advice on a good source for a vacuum pump as that's what I'd like to incorporate for the final vapor / fume extraction after they have a chance to go through the refluxing condenser and then the scrubber.

Advice or sketches would be very helpful.

Thanks

I understand the principles of why condensing is a good idea... to let the reagents work longer with less loss, but I'm not entirely sure on the best way to set a system up which would also include a fume / vapor scrubber. Before I actually start to build a fume hood and condenser / scrubber system, I'd like to know if anyone was willing to post a good schematic of their working system. Not of all the intricate details of the scrubber as such, but rather the incorporation of the condenser within the system.... ie reaction vessel / condenser / scrubber.

Somewhere along the way I'm getting confused as to how the vapors eventually leave the system after having gone through the condenser. Can anyone fill me in, or give a little advice please? And also, any advice on a good source for a vacuum pump as that's what I'd like to incorporate for the final vapor / fume extraction after they have a chance to go through the refluxing condenser and then the scrubber.

Advice or sketches would be very helpful.

Thanks